Gspeed 2015

FSAE upright structure; Second prize of FSC 2015

I was admitted to Jilin University on Sep 1st 2014, majoring in Vehicle Engineering (top 3 in China).

On Dec 14th 2014, I received an offer from the Gspeed Formula Racing Team (Gspeed) and became a member of suspension group. From this moment, I was inseparable from extreme sports and mechatronics.

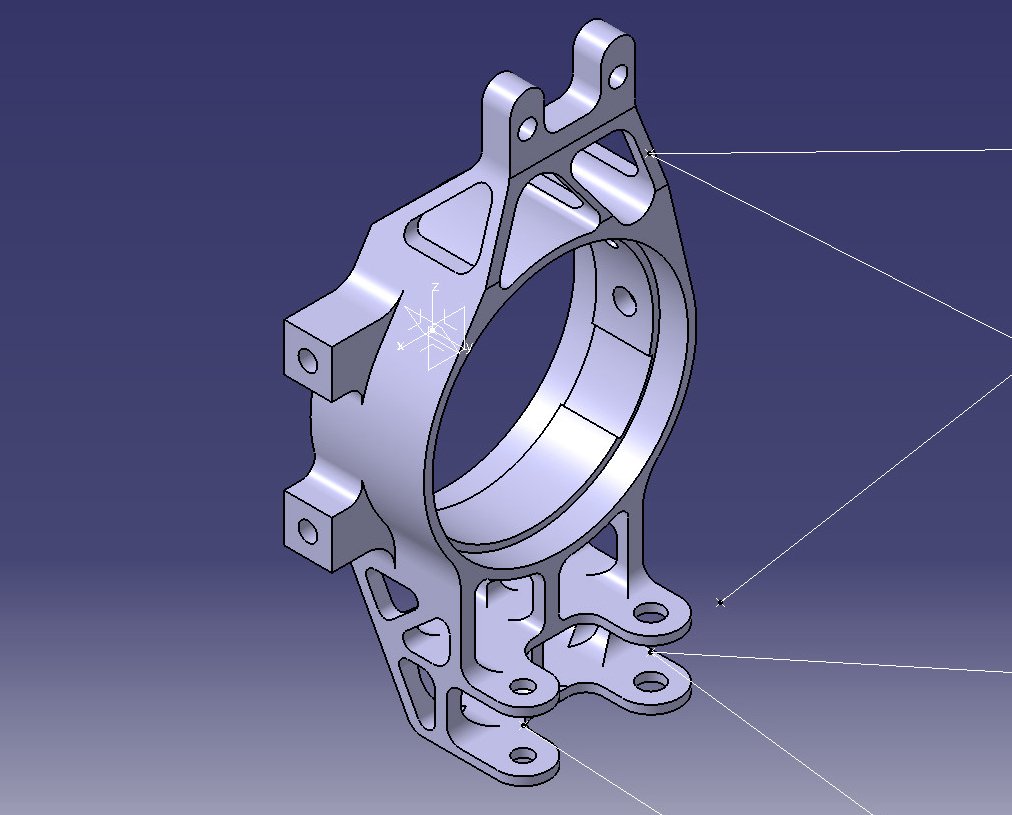

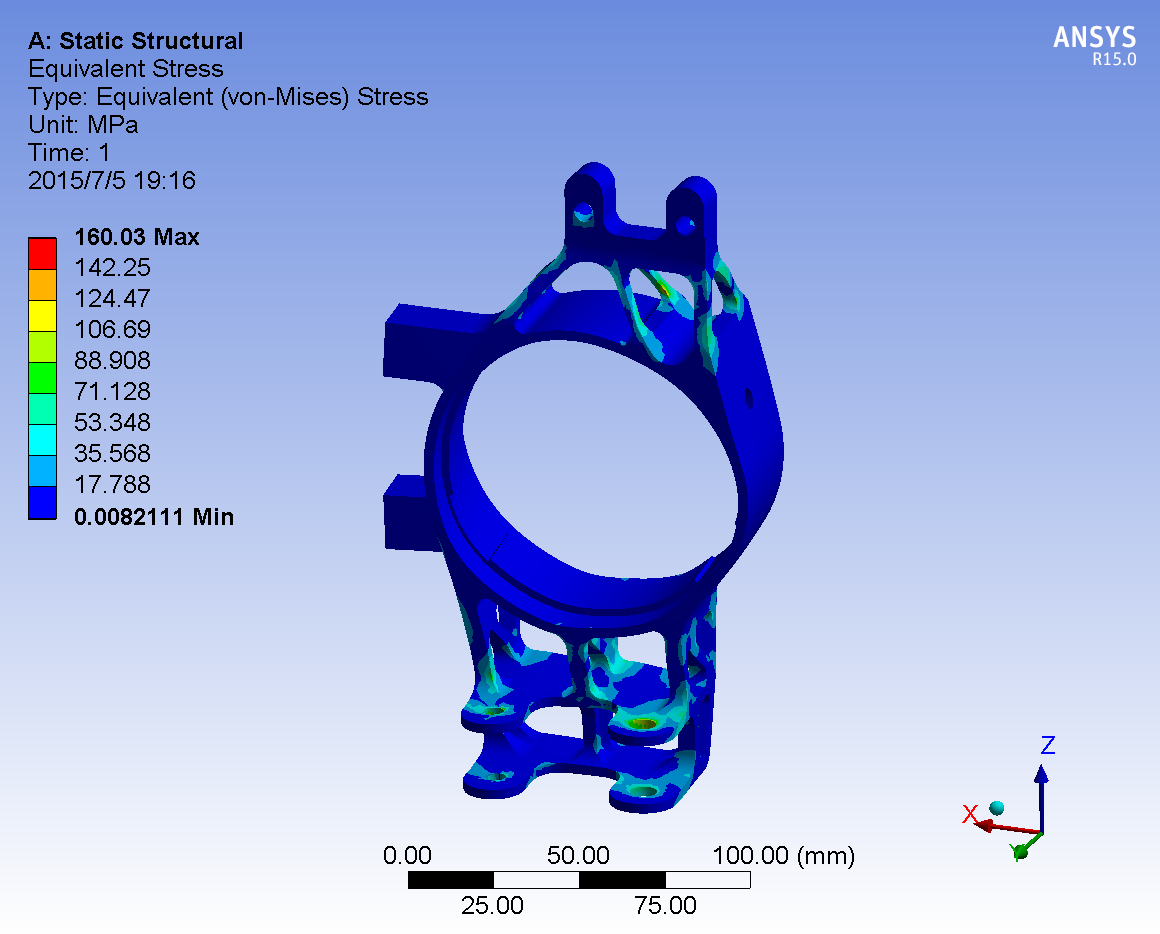

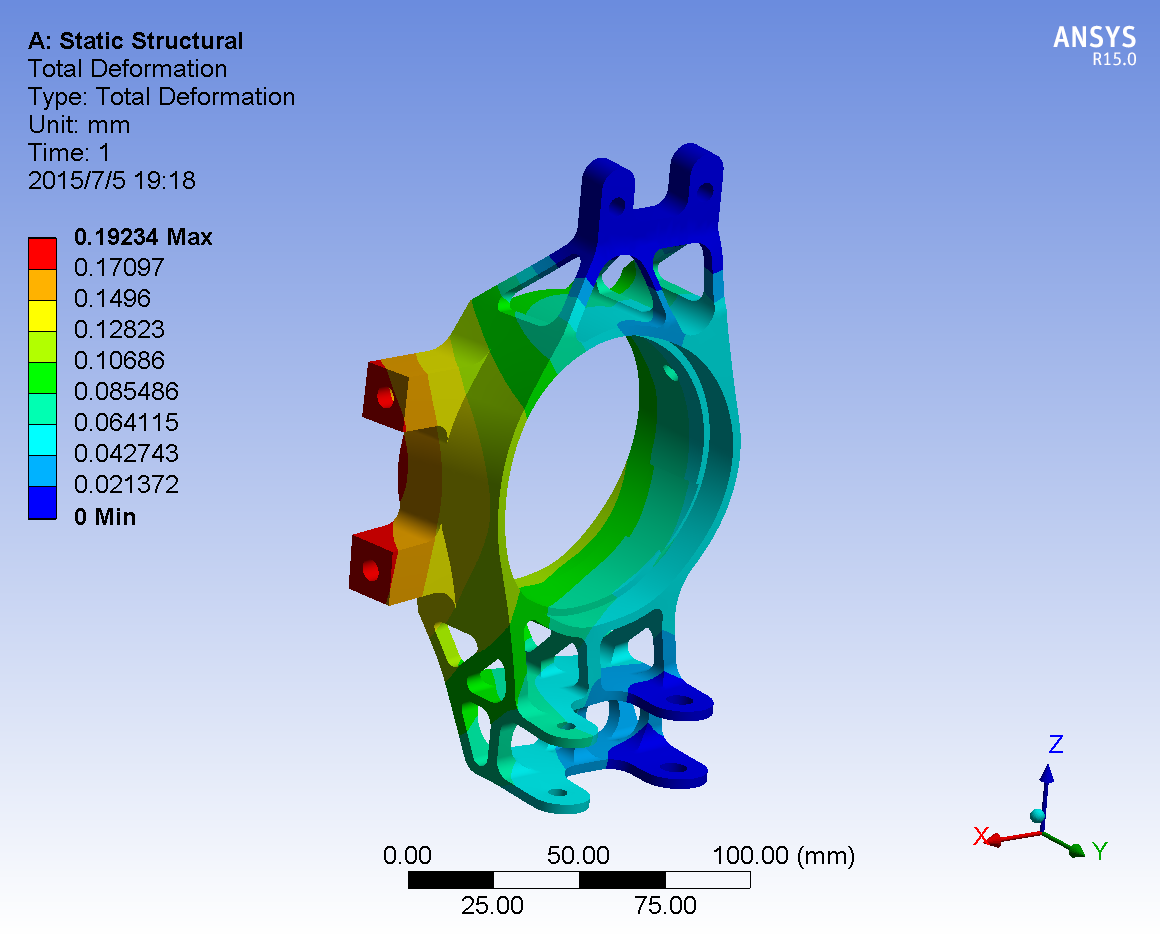

In the 2015 season, I was responsible for the mechanical design of suspension uprights. The upright (made of 7075-T6) was the largest aluminium component on Gspeed 2015. It connected the wheel hub, whisbone, brake caliper and steering arm to the vehicle, so these components transmitted great forces to it (1.5g longitudinal deceleration; 2g lateral acceleration). Reliability, strength and light weight were goals we strived for and needed to be traded off during the design process.

We designed the 3D structure in CATIA software, and then optimized its shape based on the finite element method (FEM) in ANSYS software. Through continuous optimization, the upright only weighs 297 grams while withstanding heavy loads!

This year, I also learned how to collaborate with others and saw how a team of over 100 people operates efficiently.

In Oct 2015, the car was shipped to the Xiangyang circuit for Formula Student China (FSC) 2015, where there were 67 domestic universities to pariciapte in. Our team finally won a 2nd place in Engineering Design, a 2nd prize in static events, and a 11th place (2nd prize) overall.