Gspeed 2016

FSAE suspension system; Second prize of FSC 2016

In 2016, I was promoted to the suspension group leader and was responsible for developing the Gspeed suspension system.

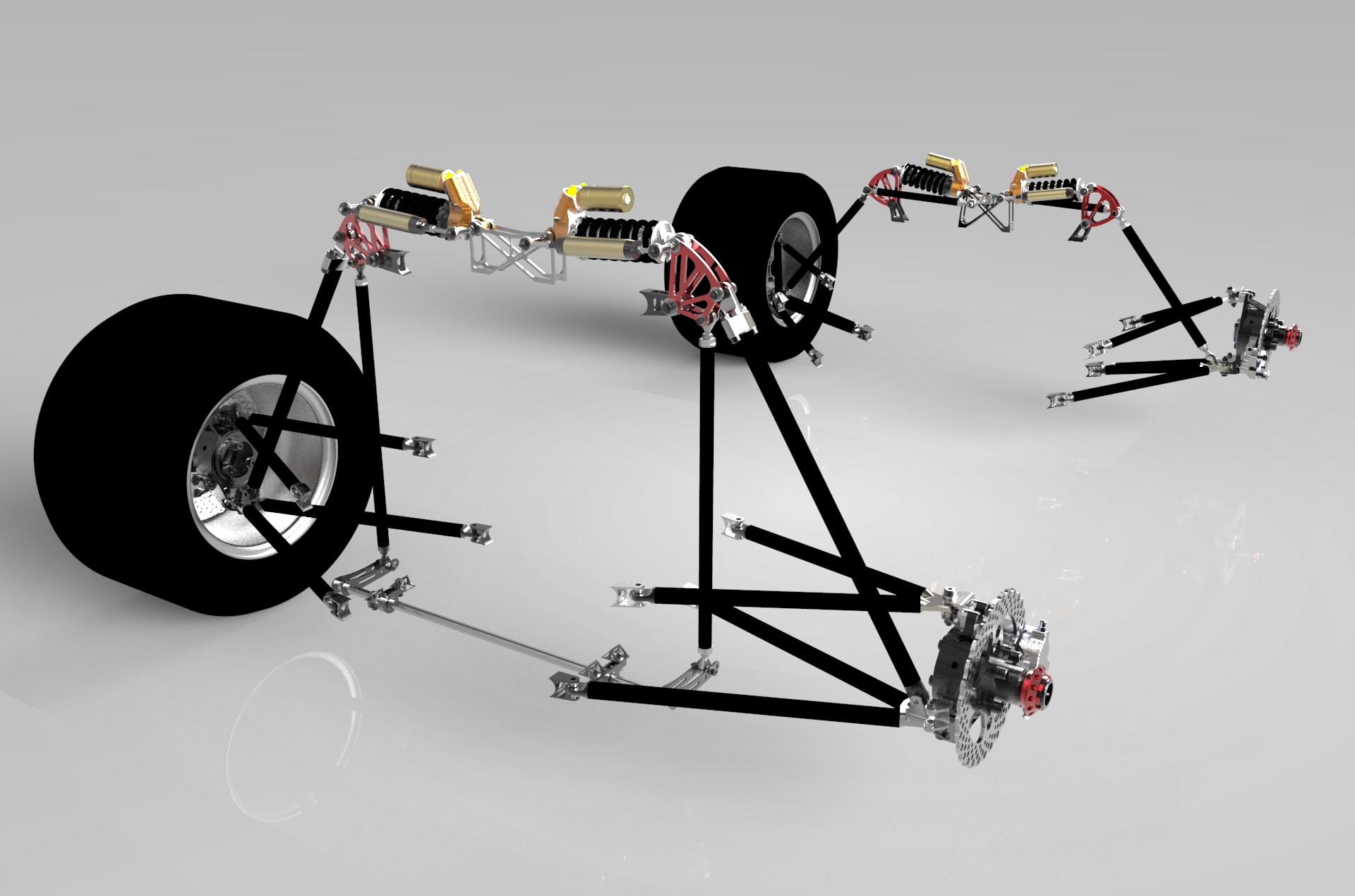

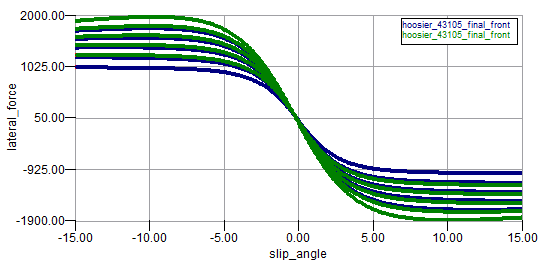

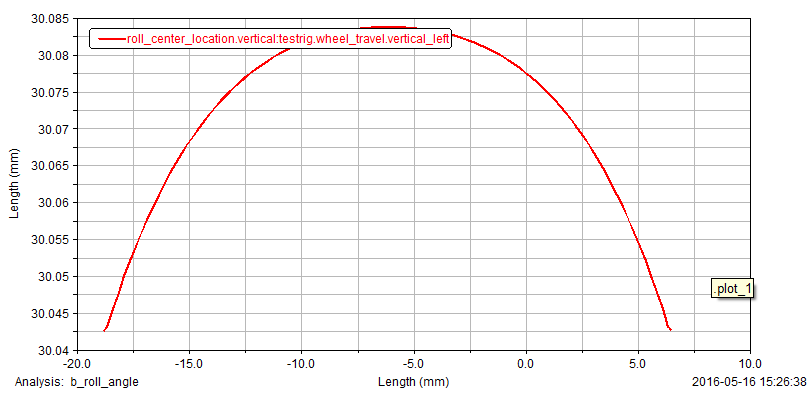

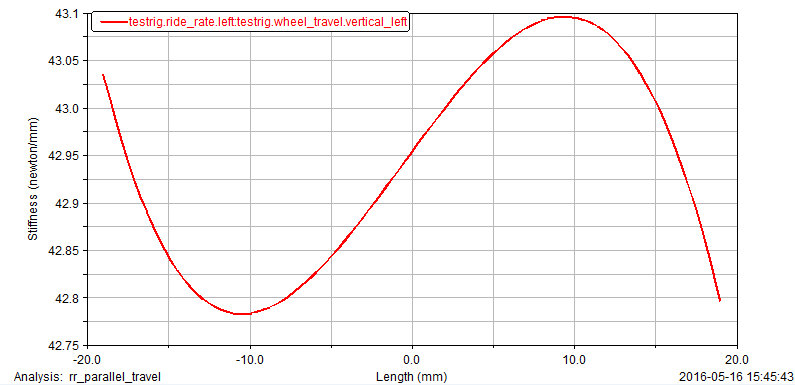

We modeled and simulated a virtual prototype of the suspension system in Adams/Car software. It was expected to have excellent handling stability by optimizing the kinodynamic characteristics of virtual components such as springs, dampers, or links. After considering the effects on each assembly, the new suspension layout (i.e., hardpoints) was essentially finalized.

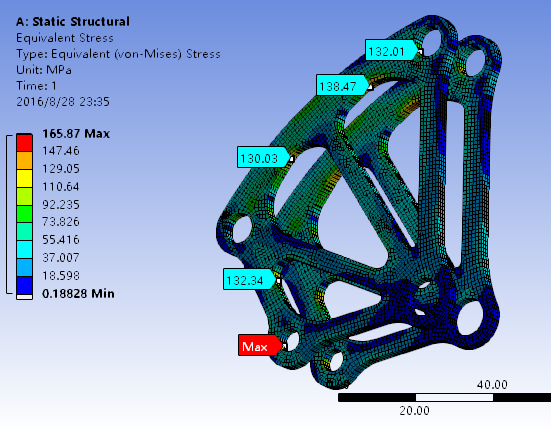

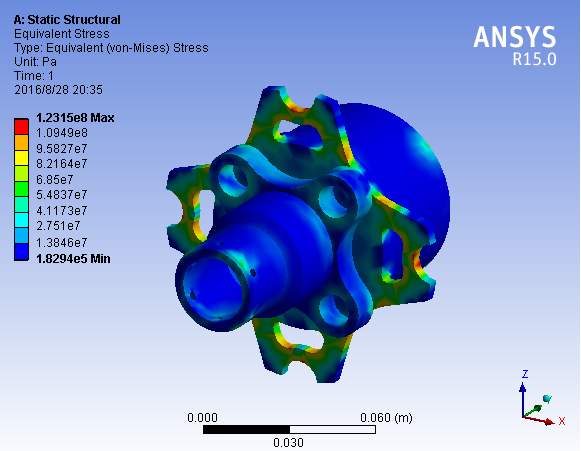

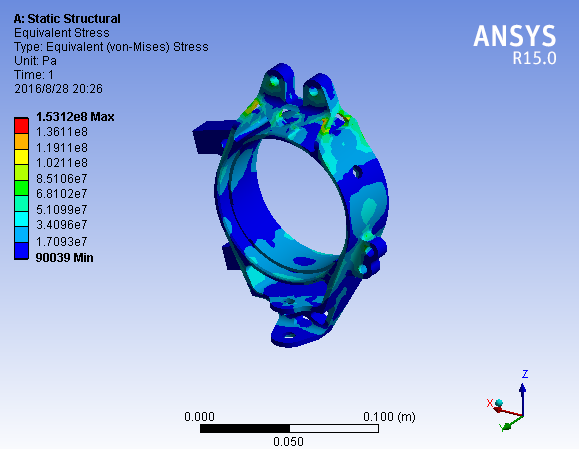

When designing specific components, we applied the finite element method (FEM) in ANSYS software to optimize their shapes, weight, and load performance. Though lightweighting was important for race cars, reliabity was our primary design goal.

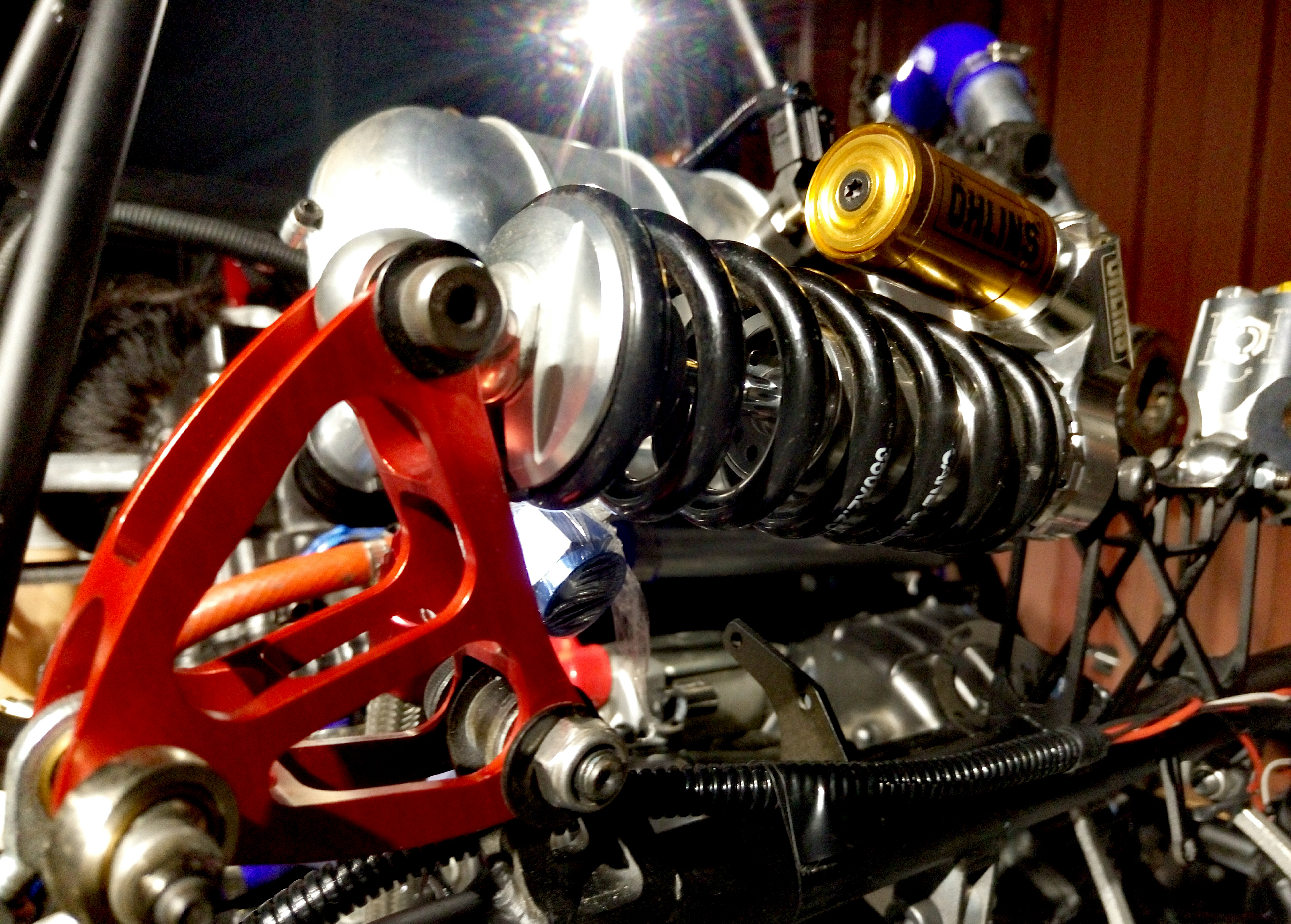

How exquisite were these mechanical parts in the real world!

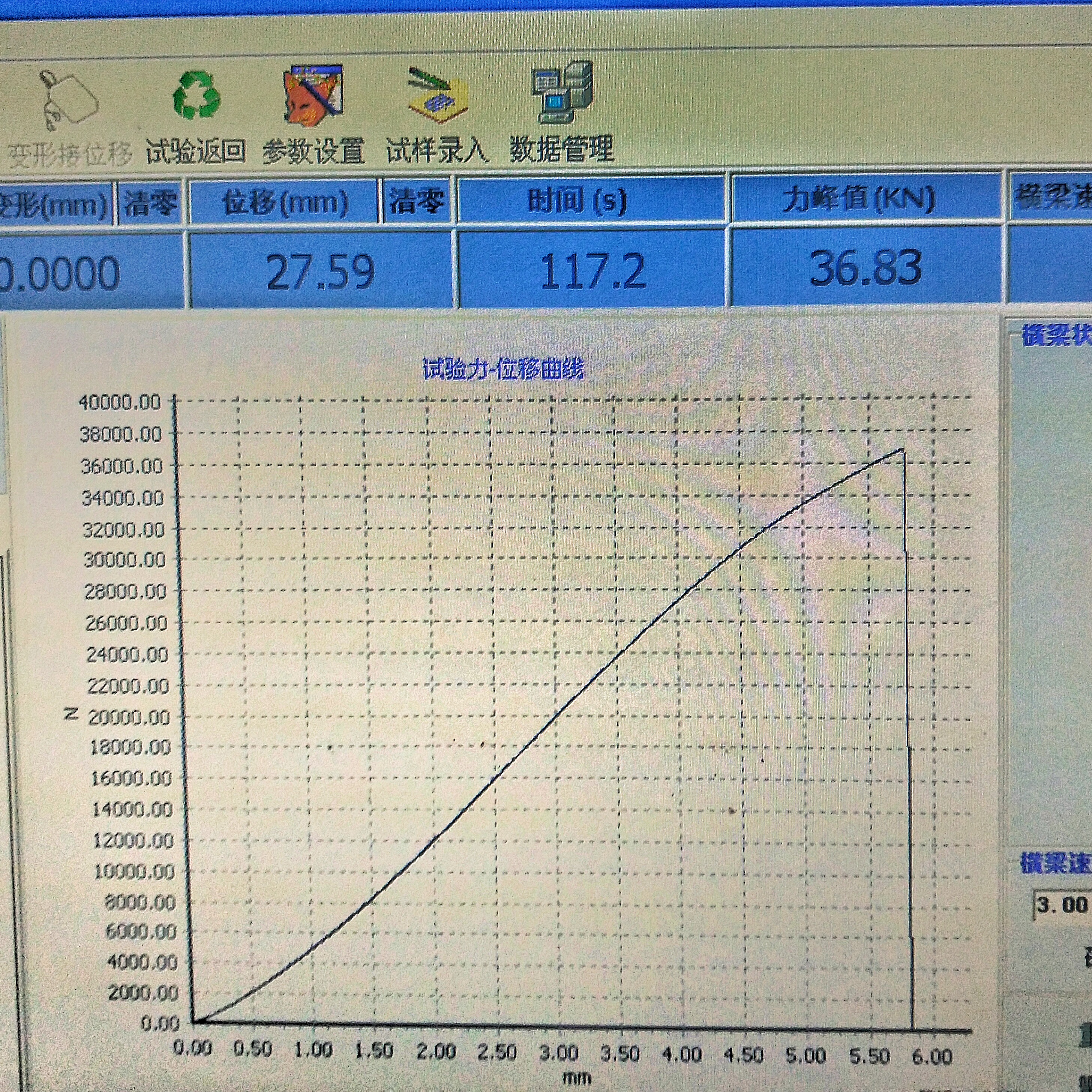

During development, we also conducted a series of component experiments to verify their actual performance. For example, we used the DP460 adhesive to attach carbon fiber wishones to aluminum joints. In failure tests, the bonded interface was not destroyed until the tensile force reached an astonishing 36.83kN!

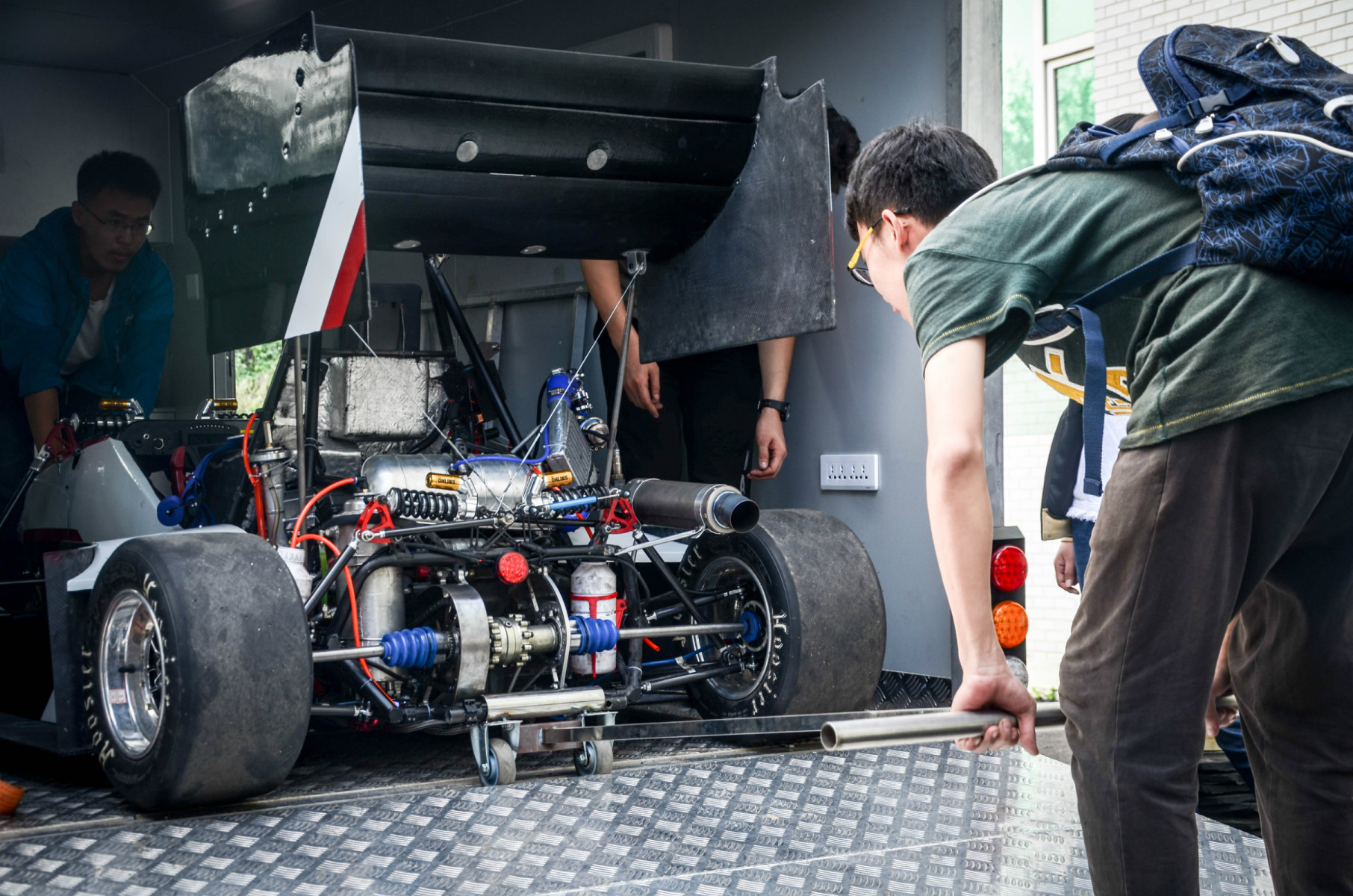

The suspension was completed and assembled with other systems. We were proud of this work and captured many beautiful photos.

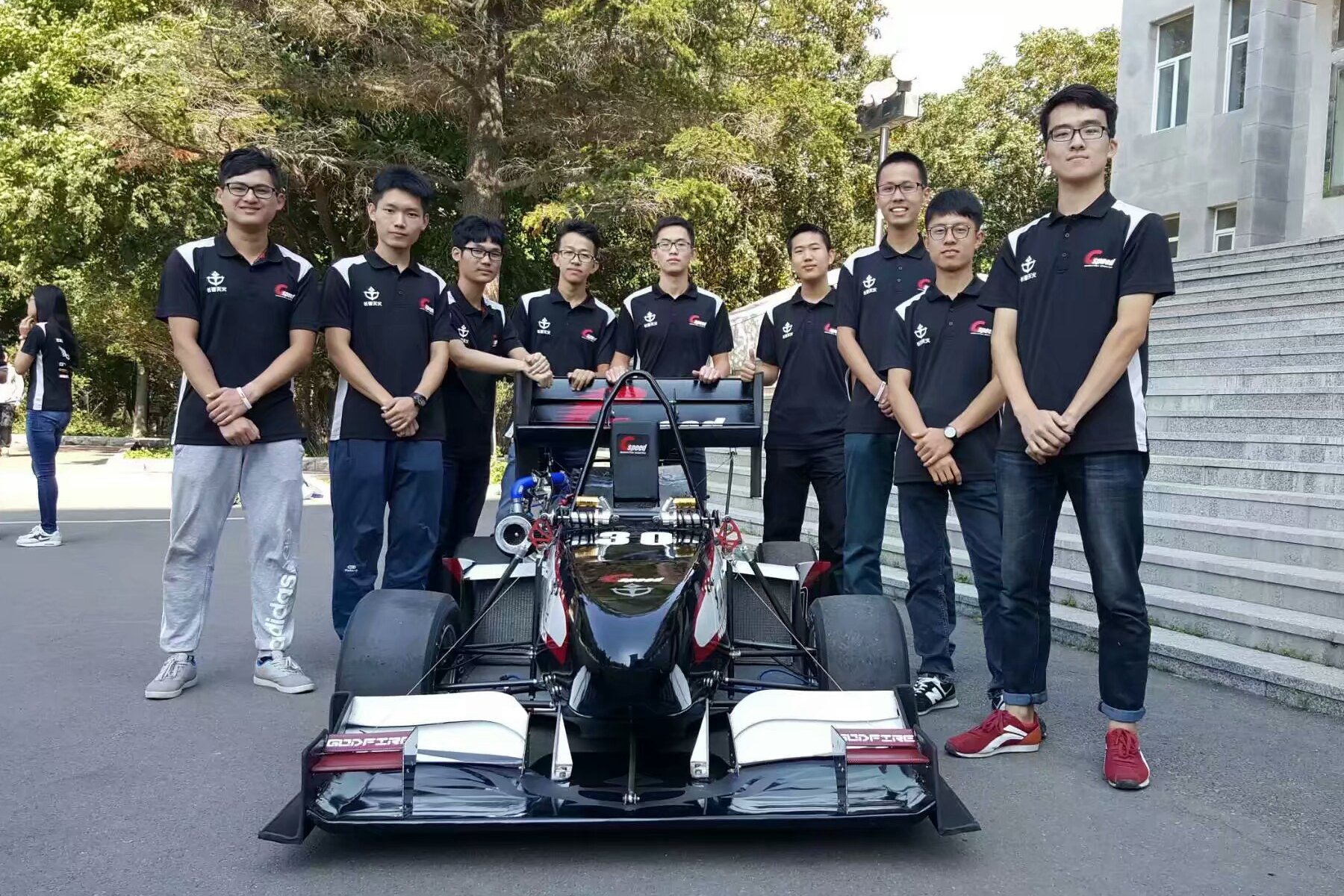

In addition to gaining more expertise, I also learned how to manage a group of R&D staff (9 people) this year.

In Oct 2016, the Gspeed race car was transported to the Xiangyang circuit for Formula Student China (FSC) 2016. A total of 69 domestic universities participated, and our team finally won a 2nd prize overall.