Gspeed 2018E

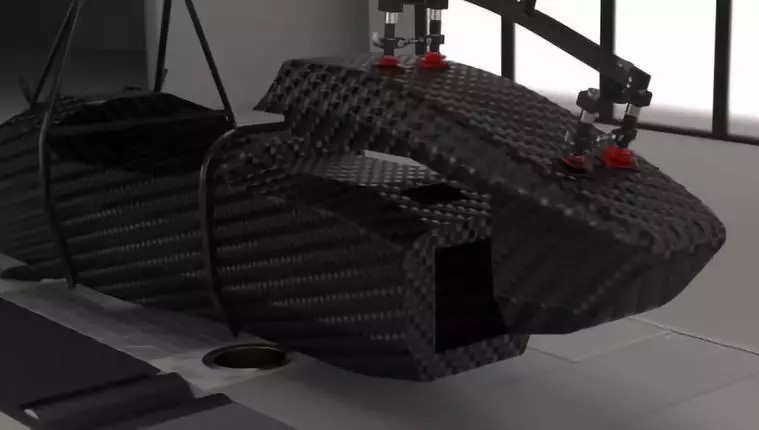

FASE CFRP monocoque; First prize of FSEC 2018

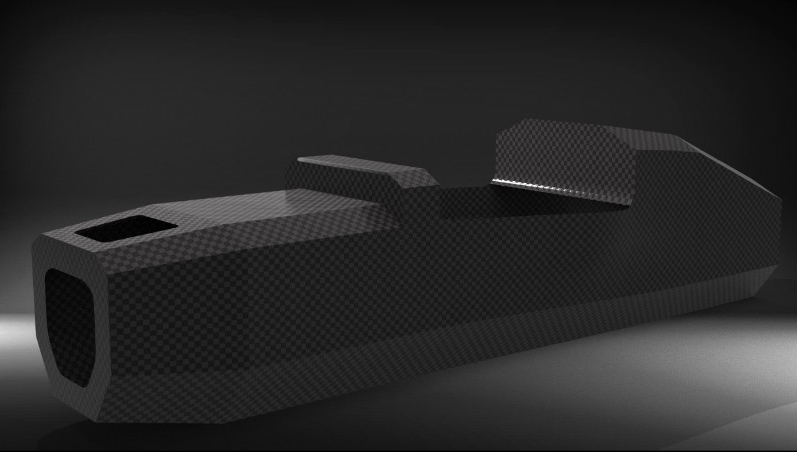

In 2018, I served as a consultant for Gspeed, providing technical support for the electric race car development (Gspeed 2018-E). This season, I was involved in the carbon-fiber-reinforced-polymer (CFRP) monocoque project as one of the initiators.

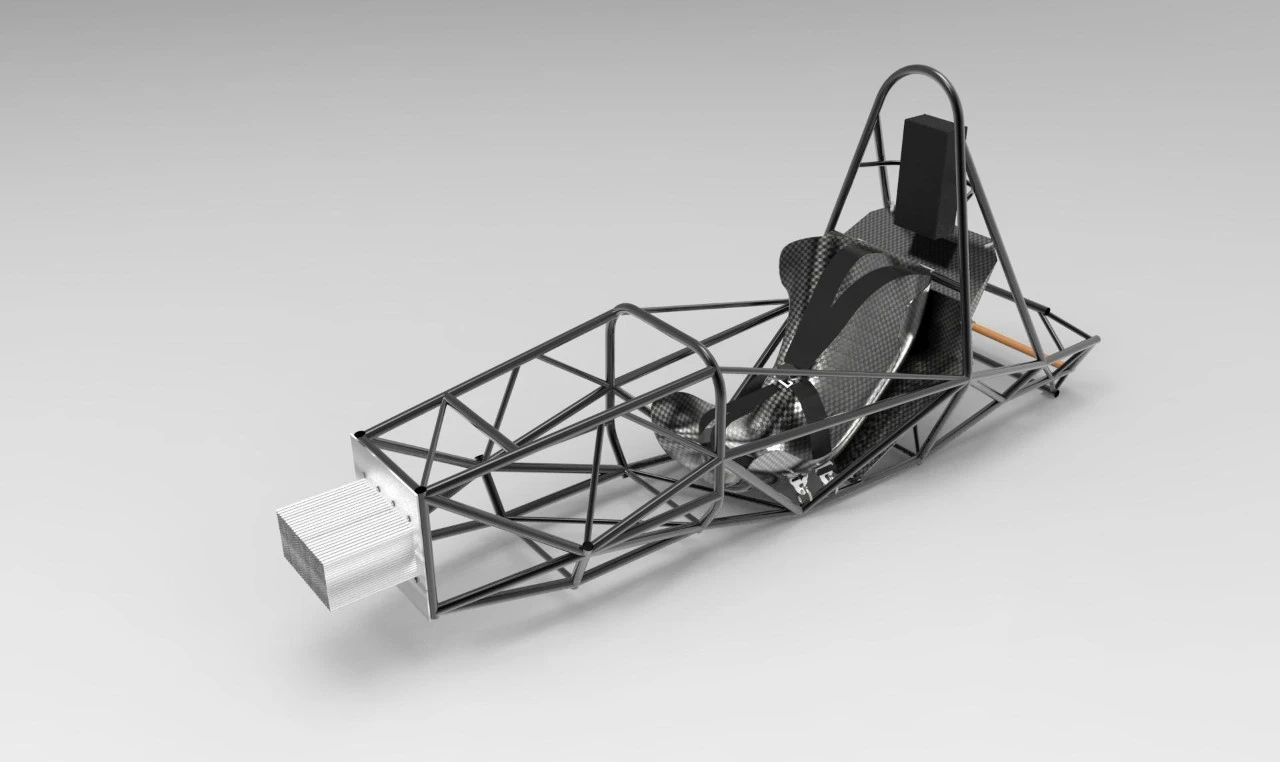

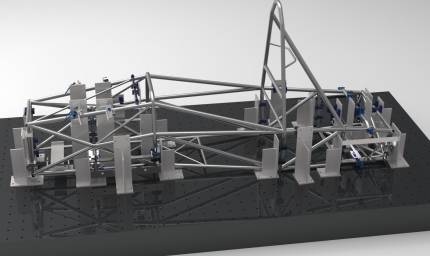

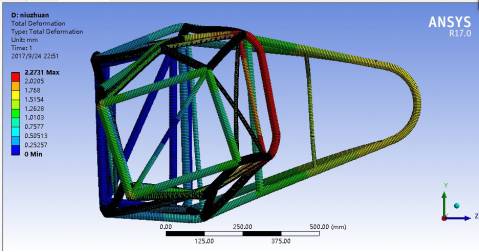

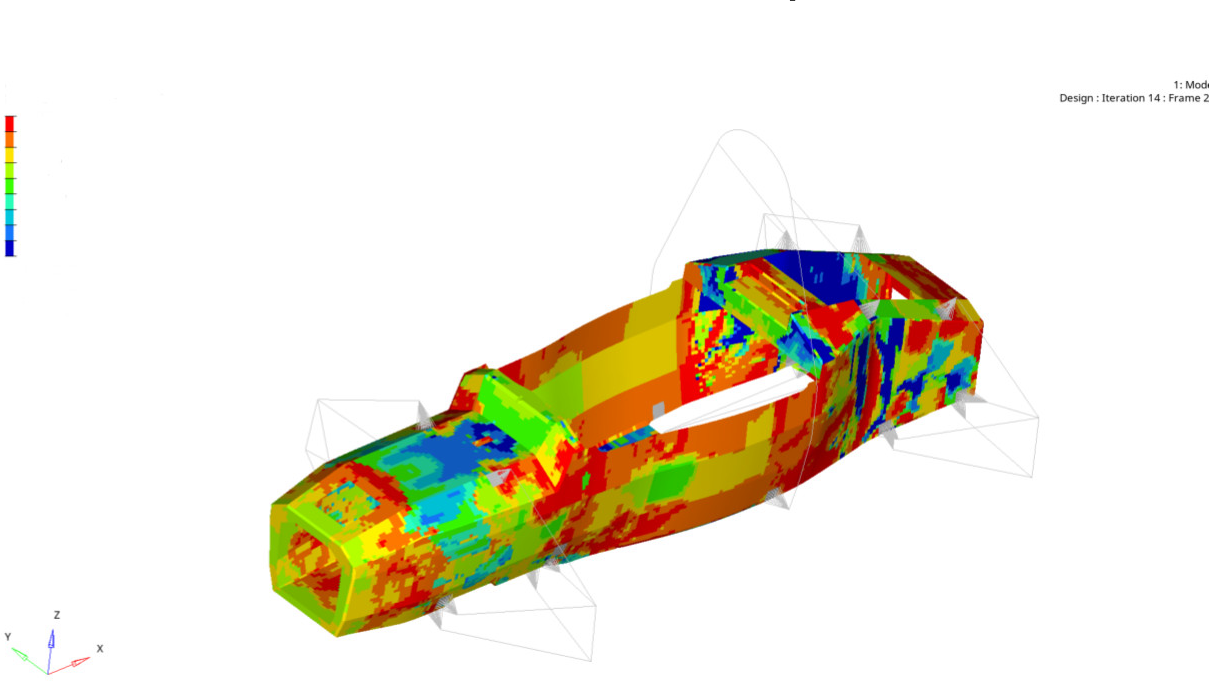

Previous cockpits were mainly made up of steel trusses (4130 / 30CrMoA). They ensured the safety of our driver and connected all vehicle subsystems, but they struggled to meet our high requirements for stiffness, precision, weight, and vibration mode.

Therefore, from this season, we adpoted the CFRP monocoque which performed much better than steel trusses.

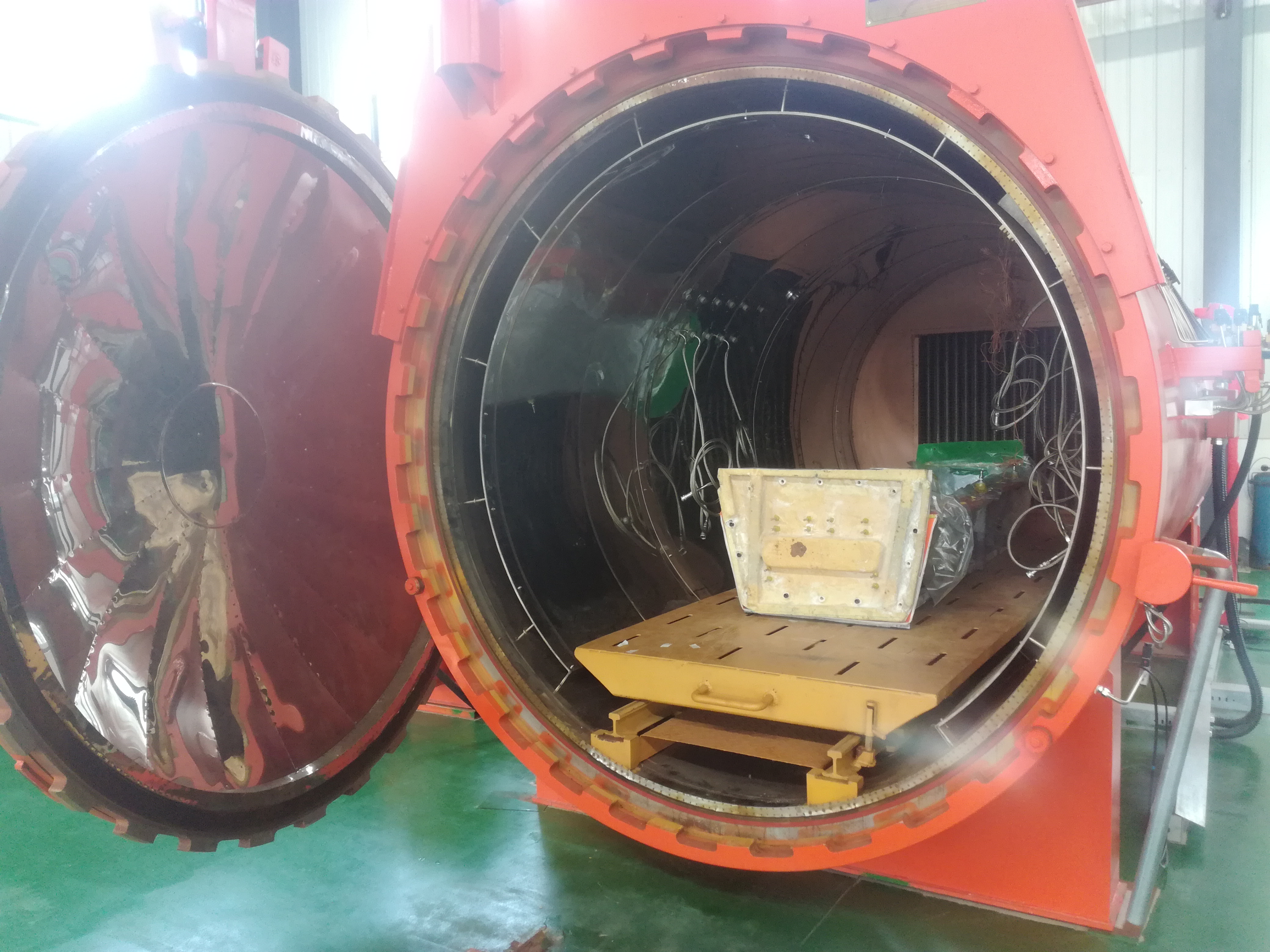

Undeniably, manufacturing such large and precise stuff (over 2.2m length) was not easy at all. We had to pay much attention to details.

I appreciated working with some optimistic guys at that time. We overcame many difficulties and made it!

In Nov 2018, the car was transported to the Zhuhai circuit for Formula Student Electric China (FSEC) 2018, where there were 48 domestic universities to pariciapte in. After a week of competition, we won the following awards:

- 4th place overall (1st prize)

- 3rd place in Engineering Design

- 2nd place in Autocross

- 2nd place in Control Strategy Development

- 1st place in MathWorks Vehicle Simulation