Quadruped Robot

Hardware and software of a 12-DoF legged robot (2021)

I started my Ph.D. at the NUS Biorobotics Lab on Aug 3rd 2020, focusing on developing novel motion planning and motion control algorithms. In addition to my research, I also participated in hardware and software development of several robotic platforms.

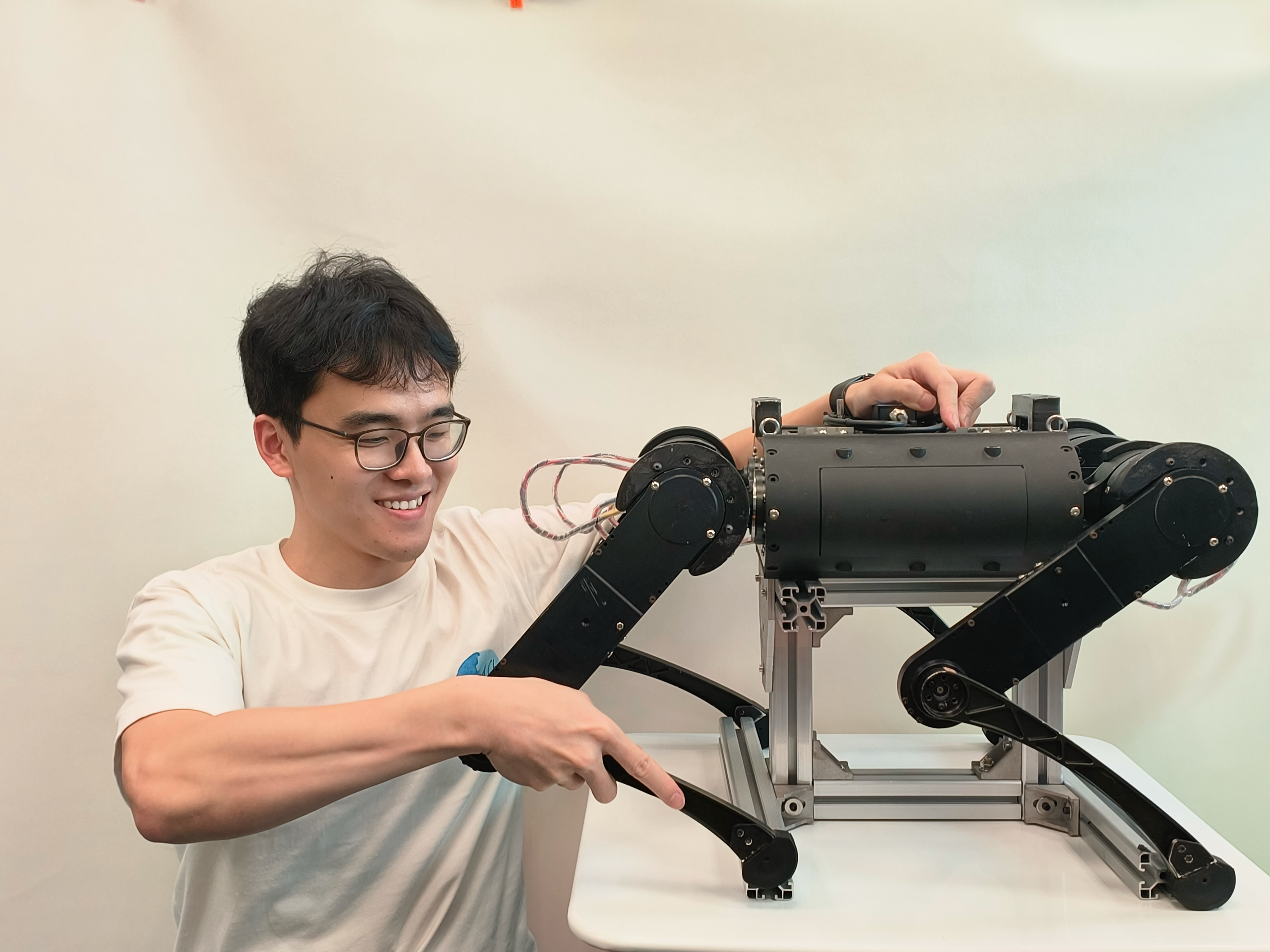

In the first year, I collaborated with 4 reseach engineers to develop a quadruped robot from scratch. Thanks to them, I had a systematic understanding of robots with high degrees of freedom (DoFs).

Project members:

- Mechanical Engineers: Shounak Bhattacharya, Xinyu Jia.

- Electronic Engineers: Xinyu Jia, Sumantra Sharma, Low Chang Hong.

- Software Engineers: Xinyu Jia, Sumantra Sharma, Low Chang Hong.

- Algorithm Engineers: Xinyu Jia, Hari Prasanth Palanivelu.

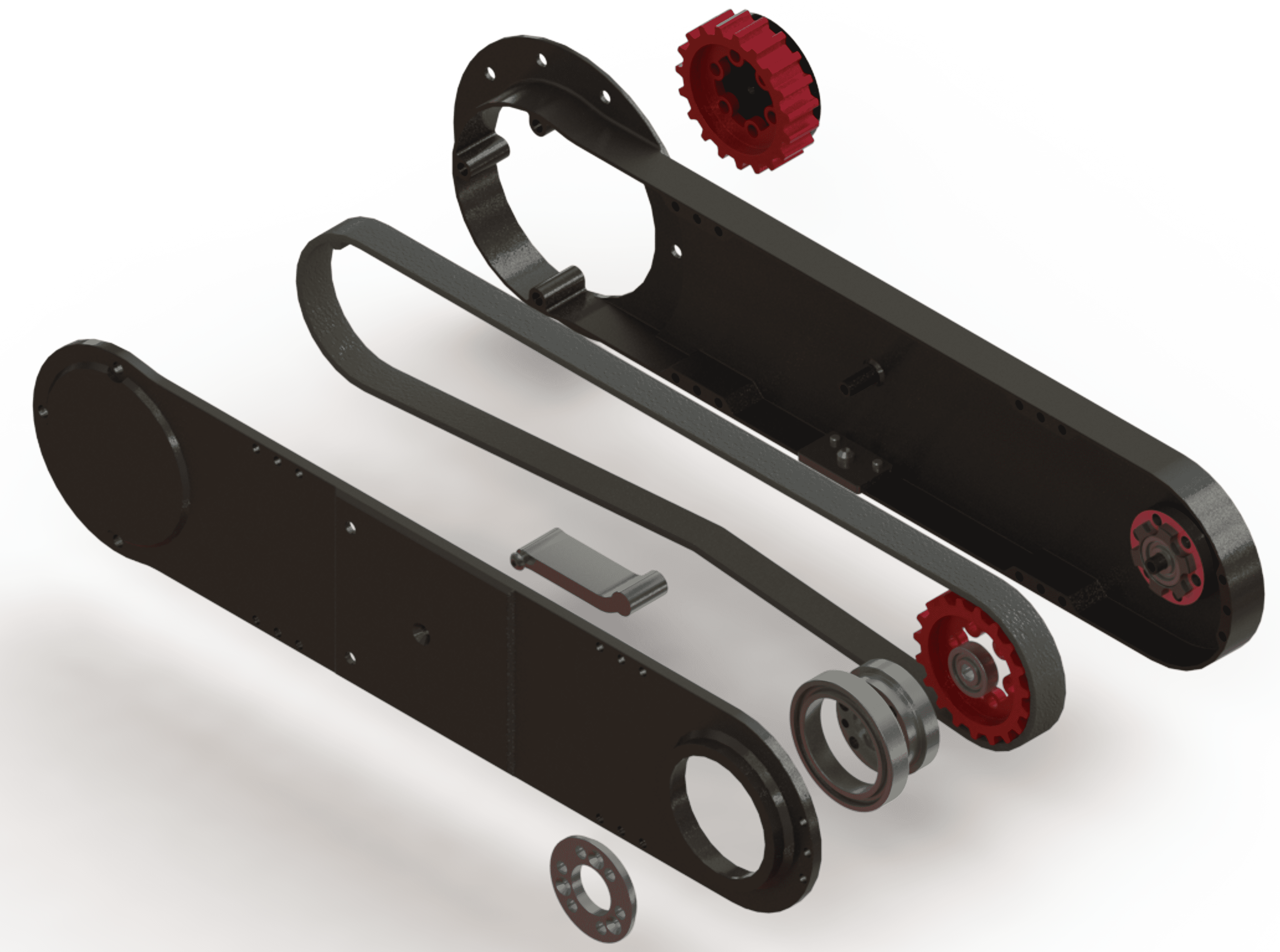

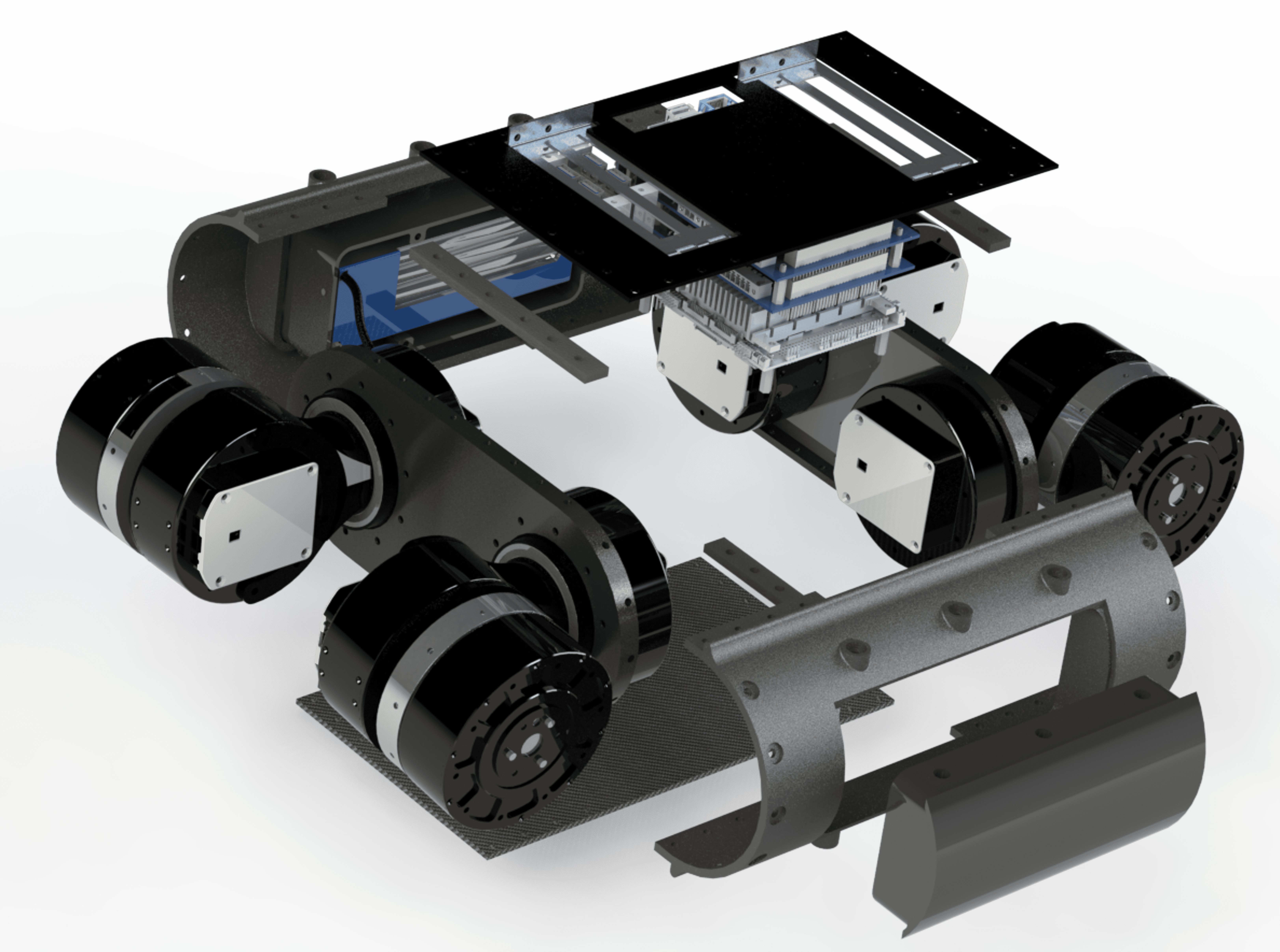

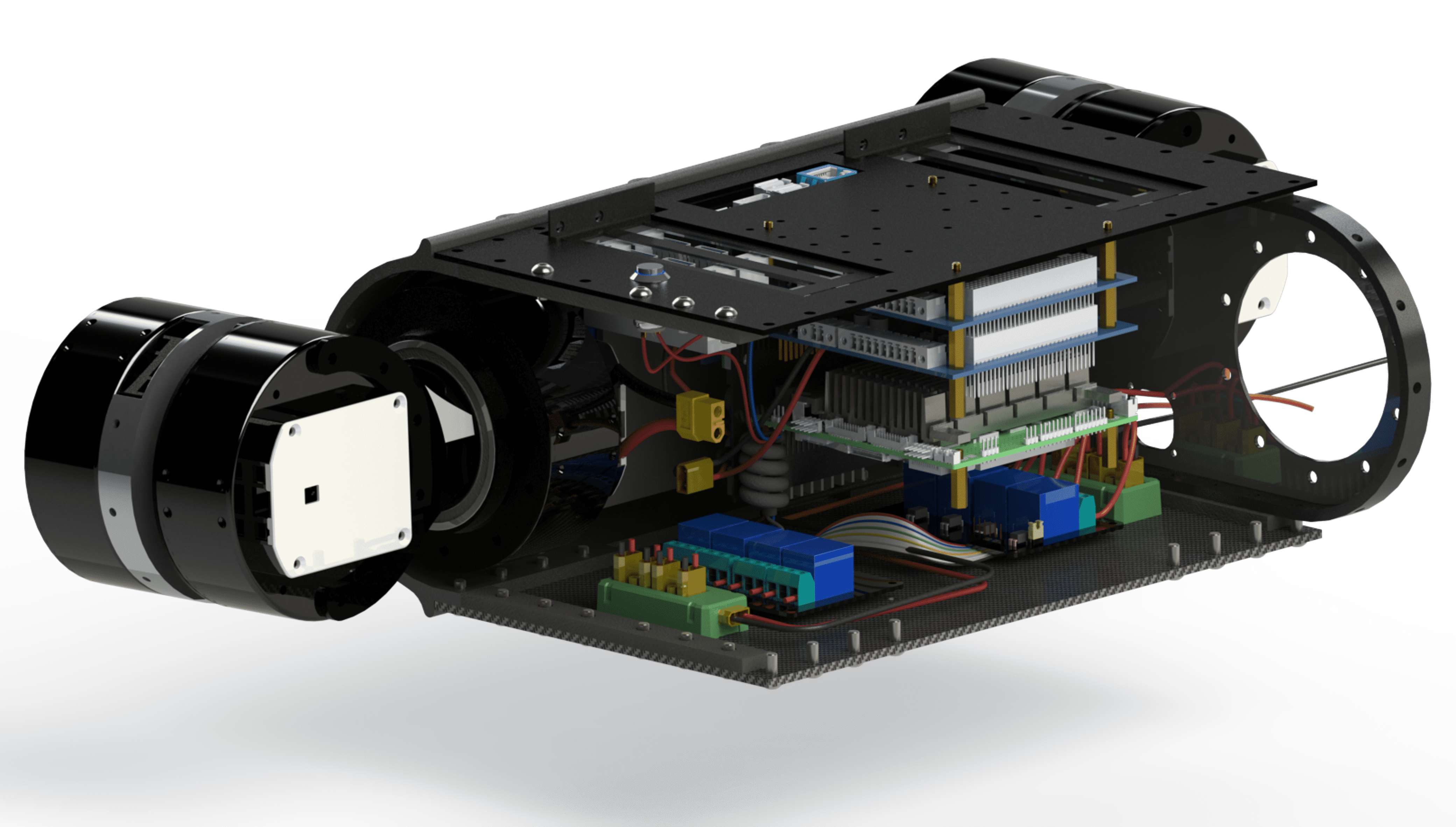

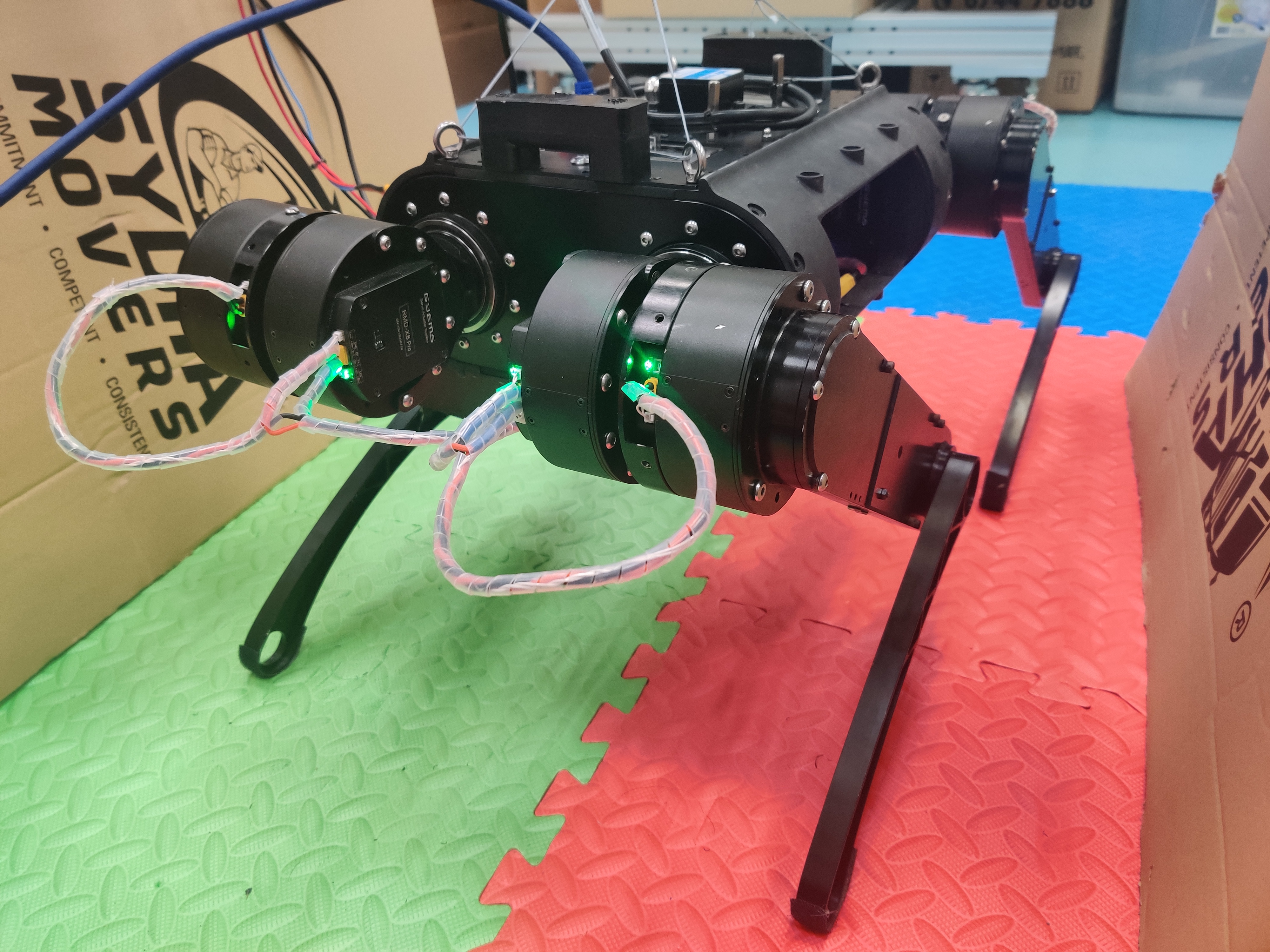

It is a 16.5kg, electrically actuated, torque-controlled, four-legged robot. The leg link can reach 0.5m when full extended. Most of mechanical components are customized, mainly made of aluminum alloy, carbon fiber, and 3D-printing material.

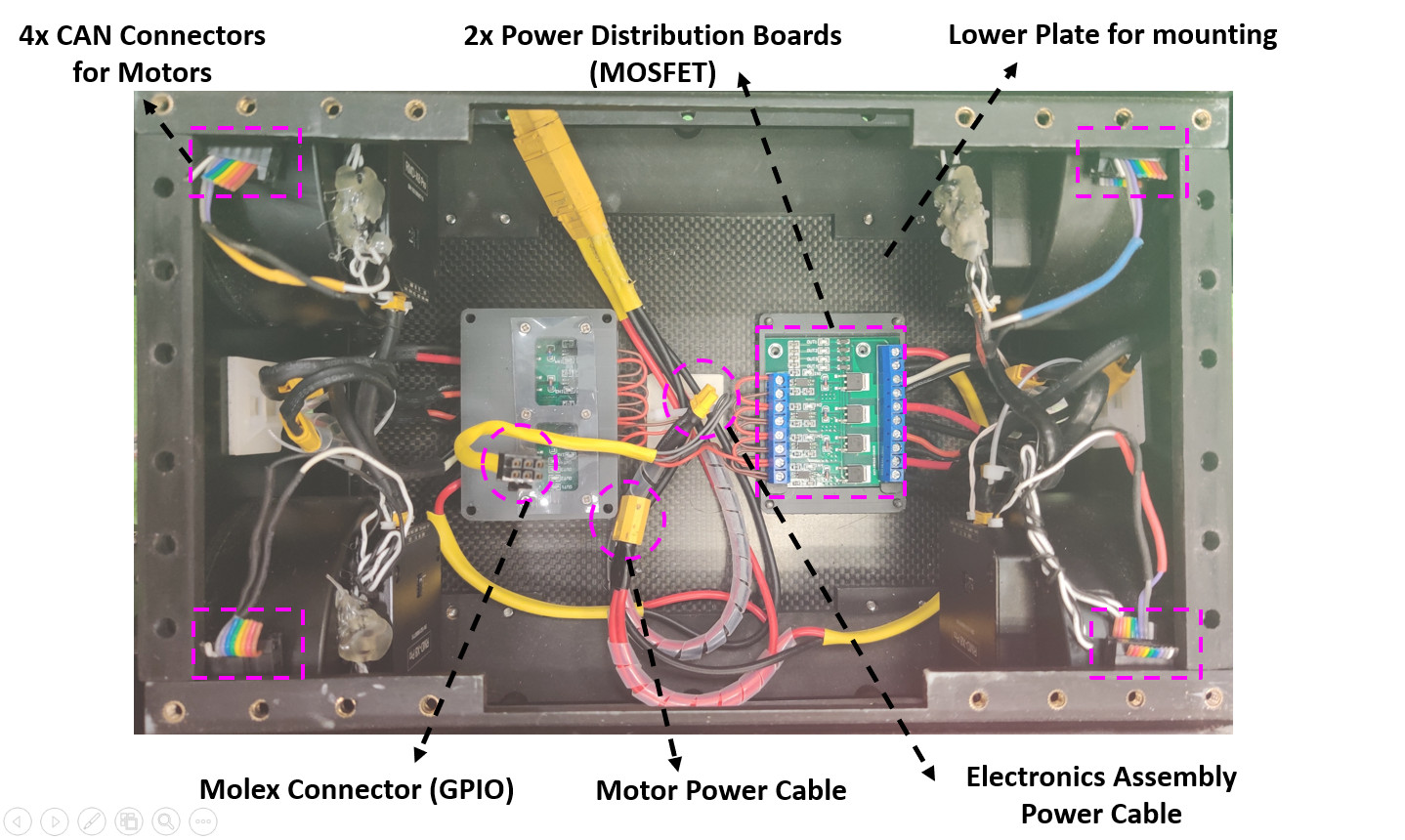

There are 12 actuated joints in total. Each joint is equipped with a (brushless DC electric) BLDC motor (GYEMS RMD X8 Pro). The motor intergates a 6:1 planetary reducer and a driver that supports 3 control modes (potision / velocity / torque).

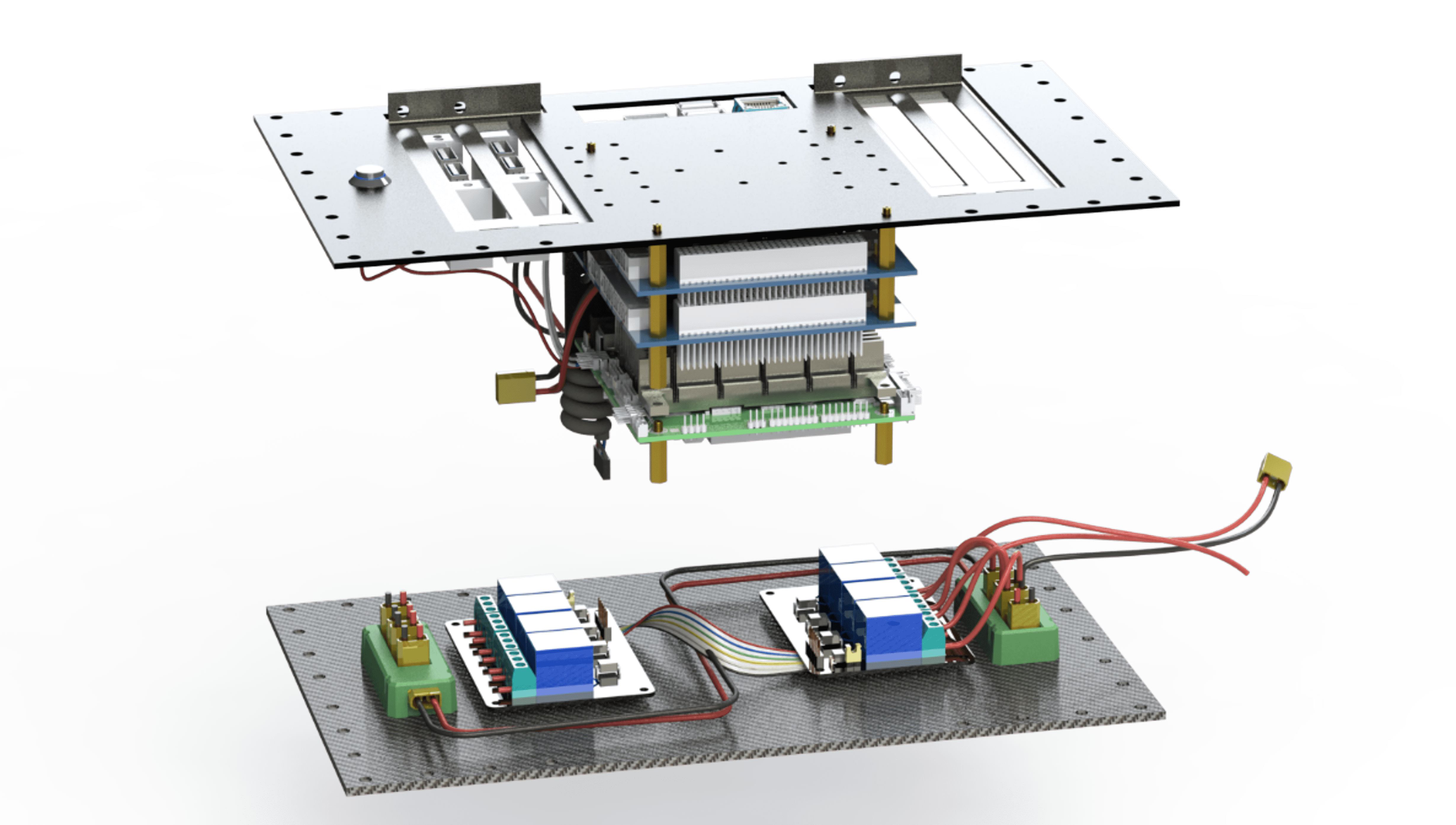

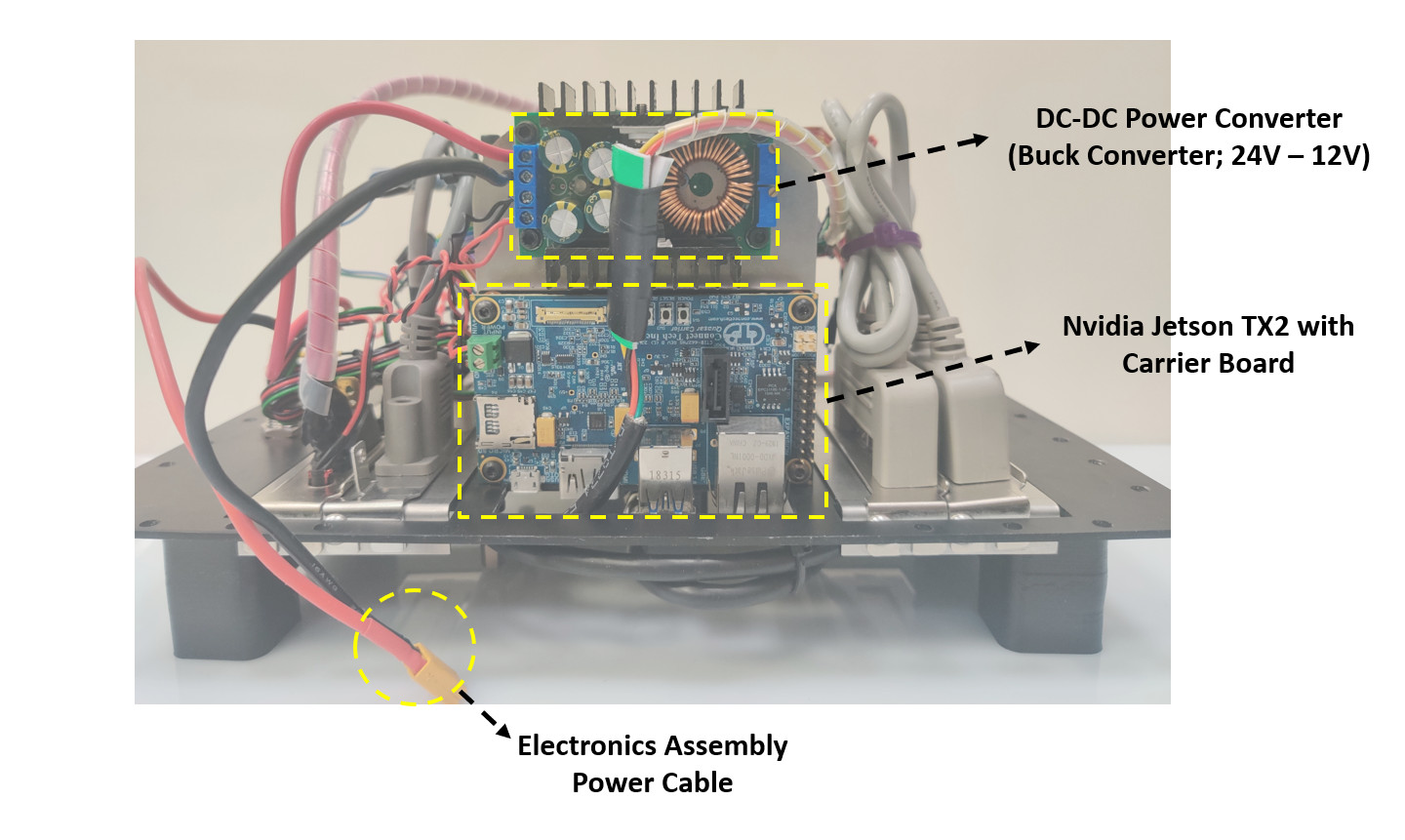

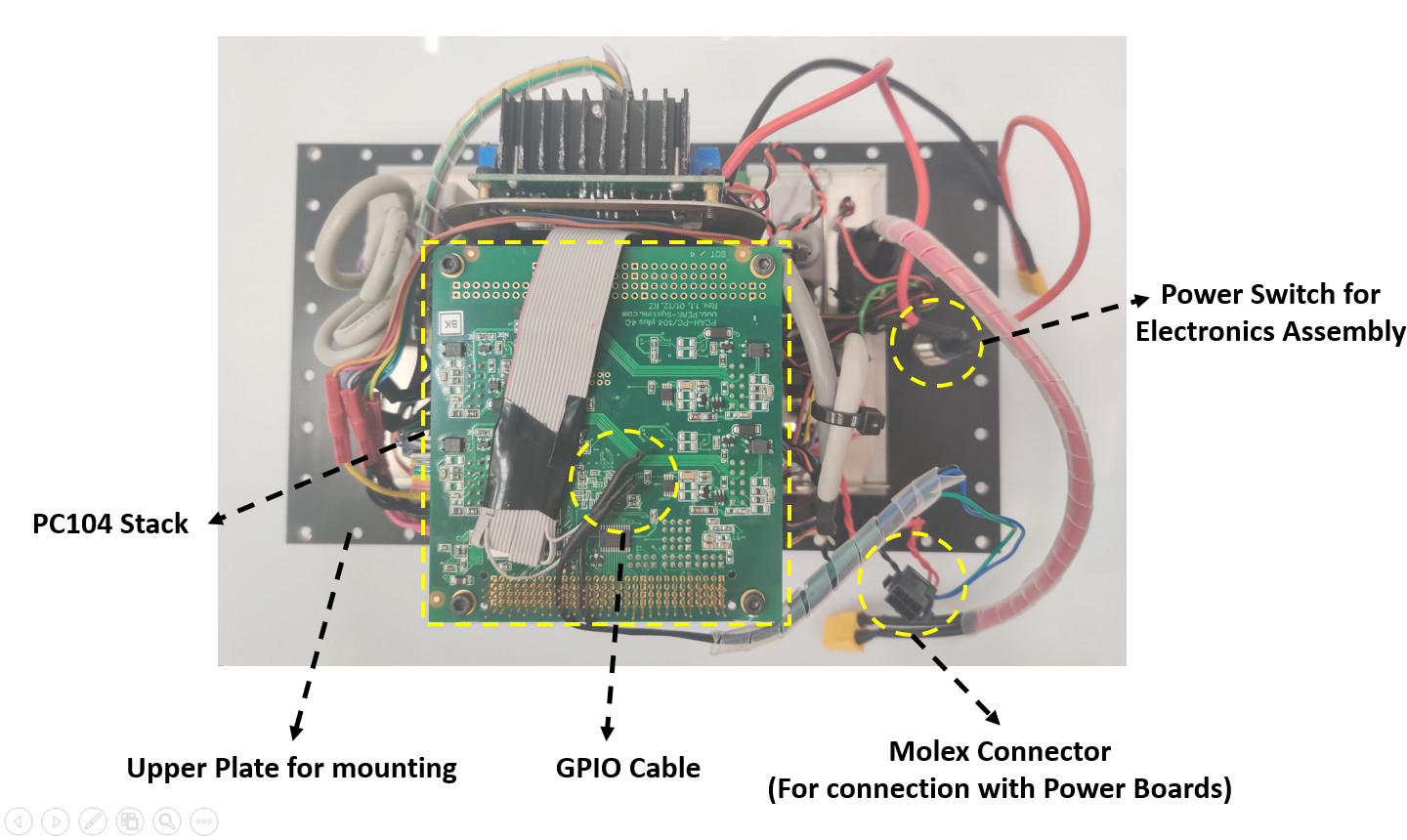

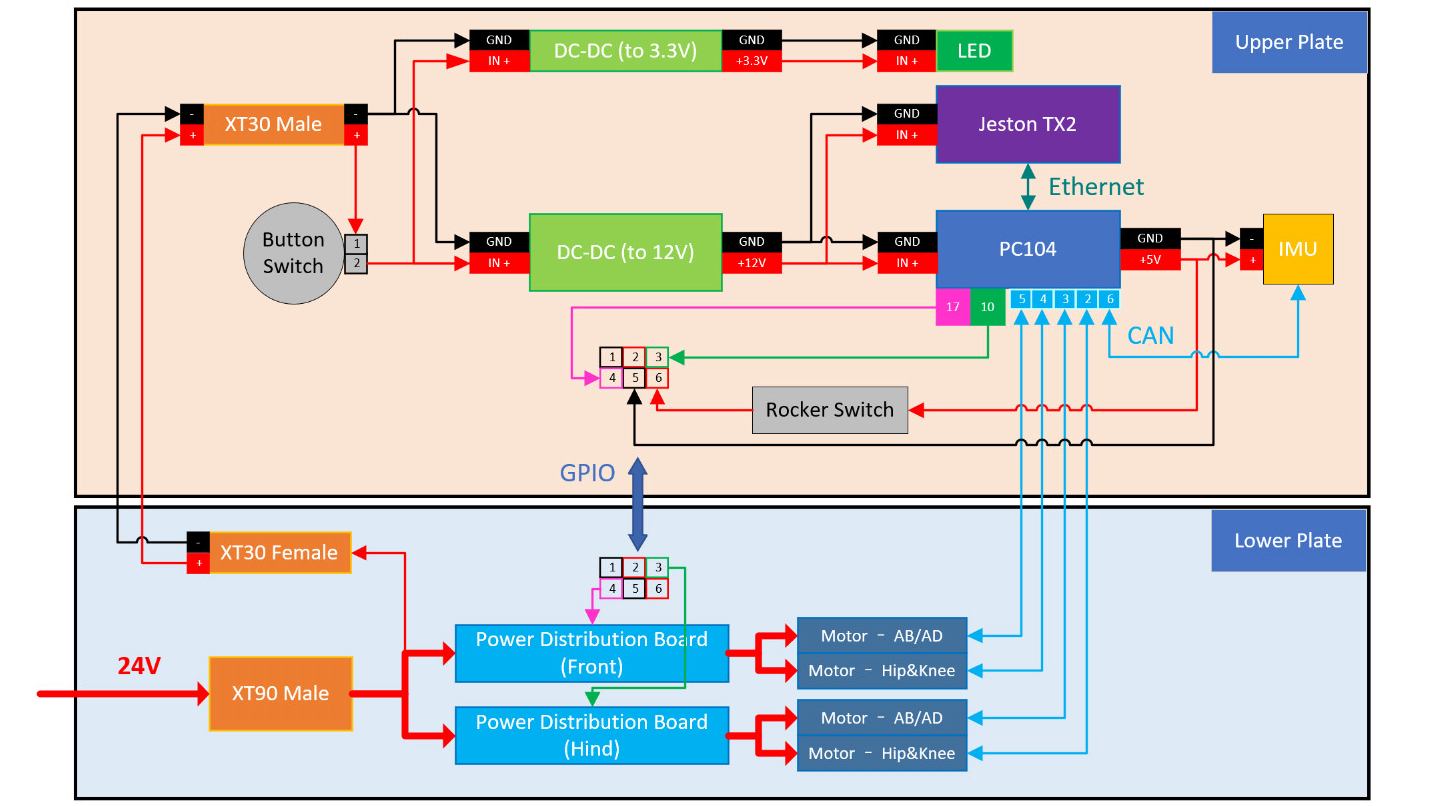

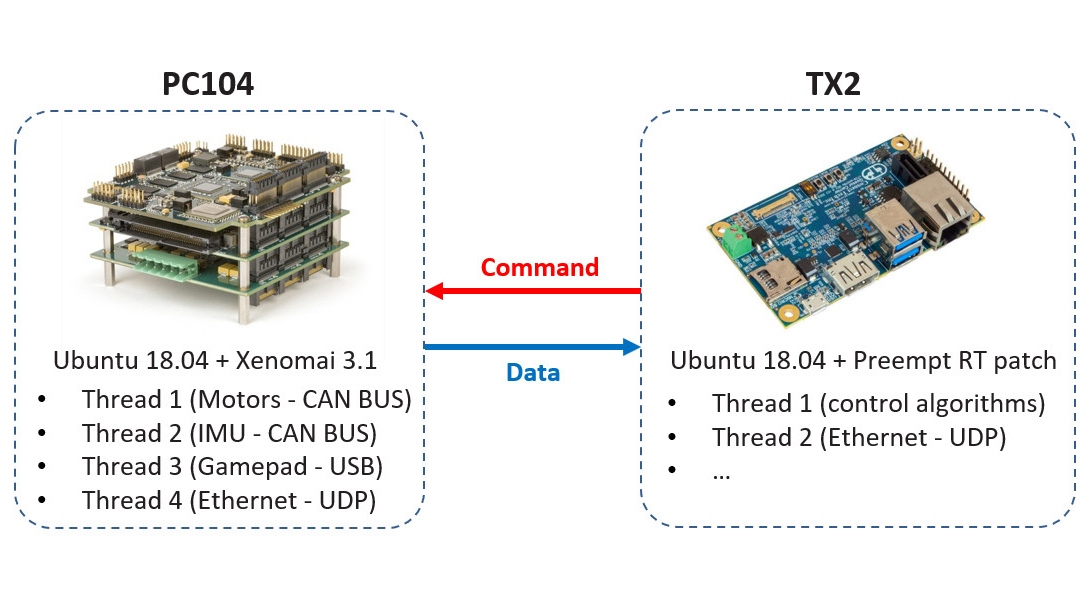

The onboard computers include an Advantech PC104 and a NVIDIA Jetson TX2. The former functions as a low-level motion controller, while the latter runs high-level control and learning algorithms. In terms of sensing, each joint has a encoder, and the robot body has a 9-axis inertial measurement unit (IMU) (WitMotion HWT901B) for state estimation.

The robot is powered by a 24V 6000 mAH Li battery. Three voltages are available for electronics: 24V - motors, 12V - computers, 3.3V - LEDs and switches. These devices communicate with each other via different protocols including CAN, UDP and USB.

The robot’s real-time software architecture allows code to run in isolated threads, which are bound to different CPUs.

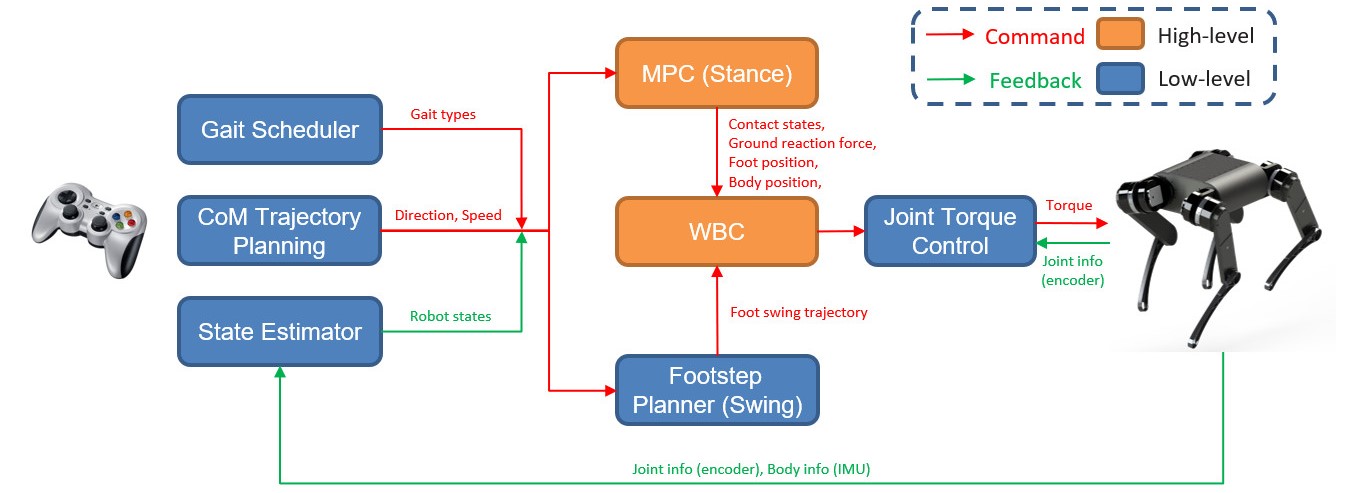

We develop the locomotion controller based on the well-known Mini Cheetah. The hierarchical control framework consists of:

- a model predictive controller (MPC) computing desired body position, body orientation, and foot force in a short horizon.

- a whole-body controller (WBC) prioritizing tracking tasks and computing joint position, velocity and torque command.

- several low-level modules processing user instructions or sensor feedback for the high-level controllers.

The algorithm is verified in ROS/Gazebo. The videos below show three robot states: “balanced stand”, “stand up”, and “trot”.

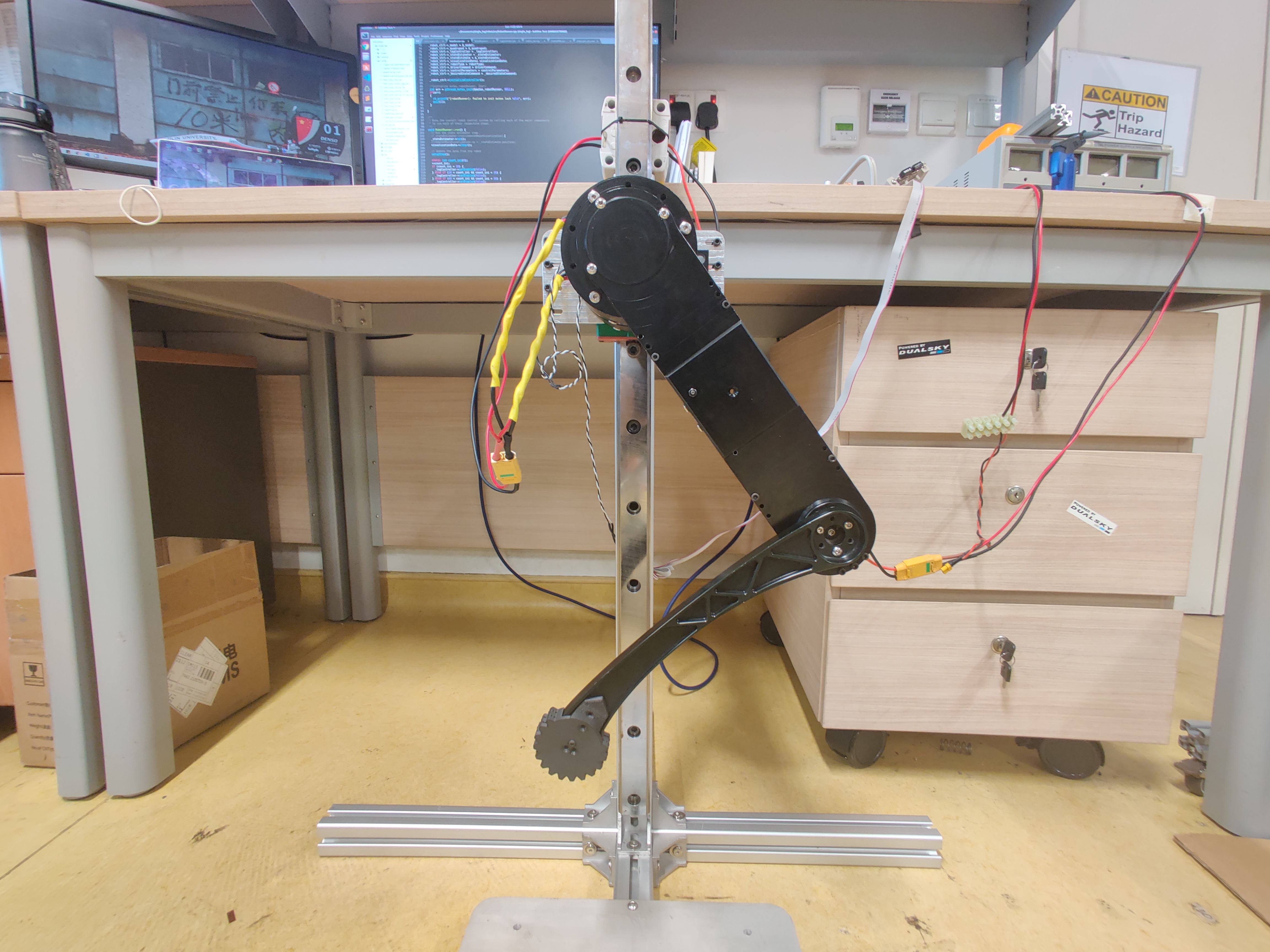

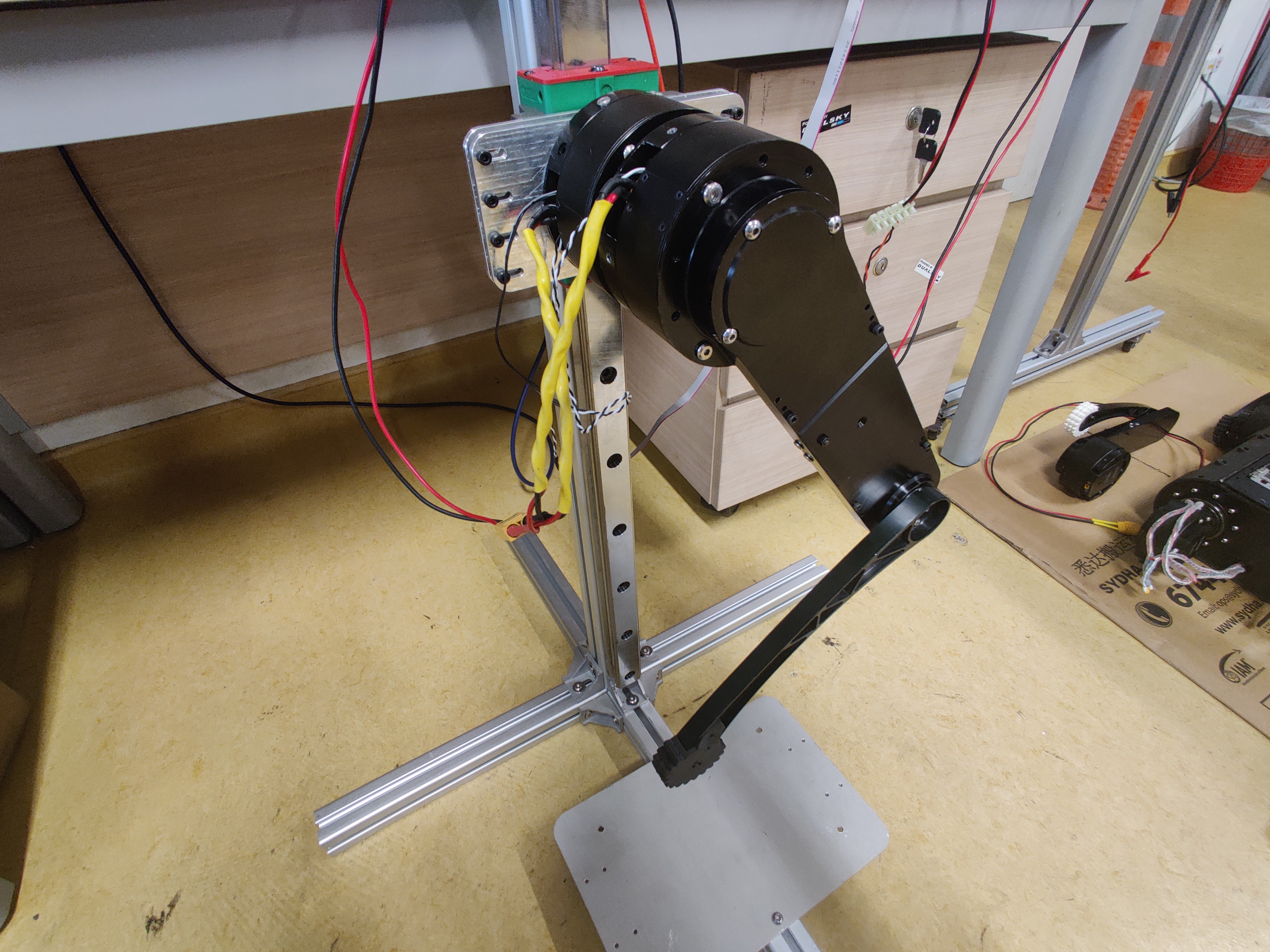

Simultaneously, we conduct single-leg hardware experiments on a bench.

The completed robot can’t wait to run on the ground!

We command the quadruped robot to trot indoors and outdoors. Its agile maneuvers demonstrate good locomotion performance.