Robotic Manipulator

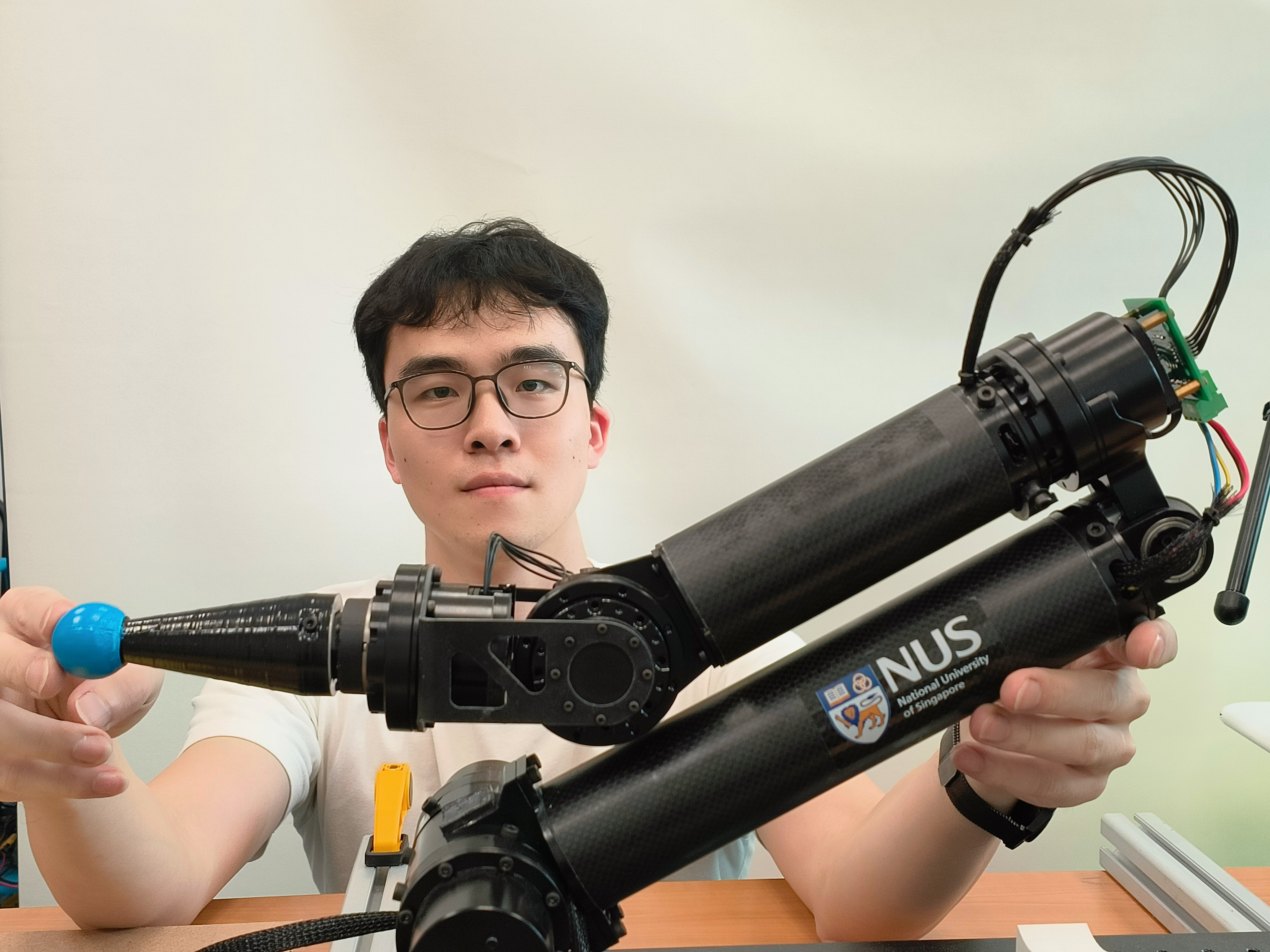

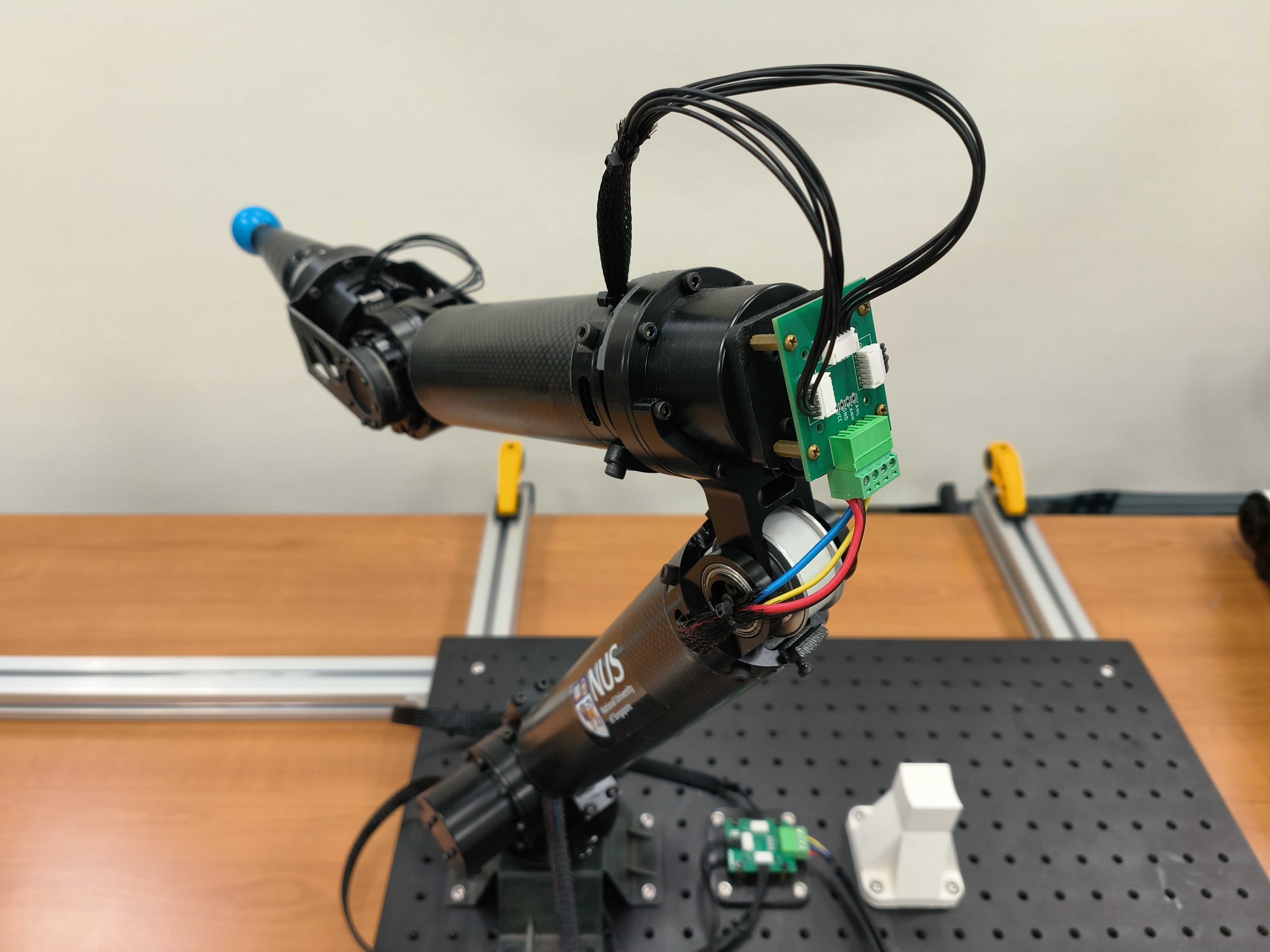

Hardware and software of a 6-DoF robotic arm (2022)

In my second year at the NUS, I was responsible for developing a cooperative robotic manipulator. It has the following features:

- 3.5kg weight

- 1kg payload @ 0.6m full extension

- 6 degrees of freedom (DoFs)

- position/velocity/torque control modes

- full robot dynamic model

- physical human-robot interaction (pHRI)

Project members:

- Mechanics: Terry Cavan Chan, Xinyu Jia, Haotian Guo.

- Electronics: Xinyu Jia, Low Chang Hong.

- Software & Algorithm: Xinyu Jia.

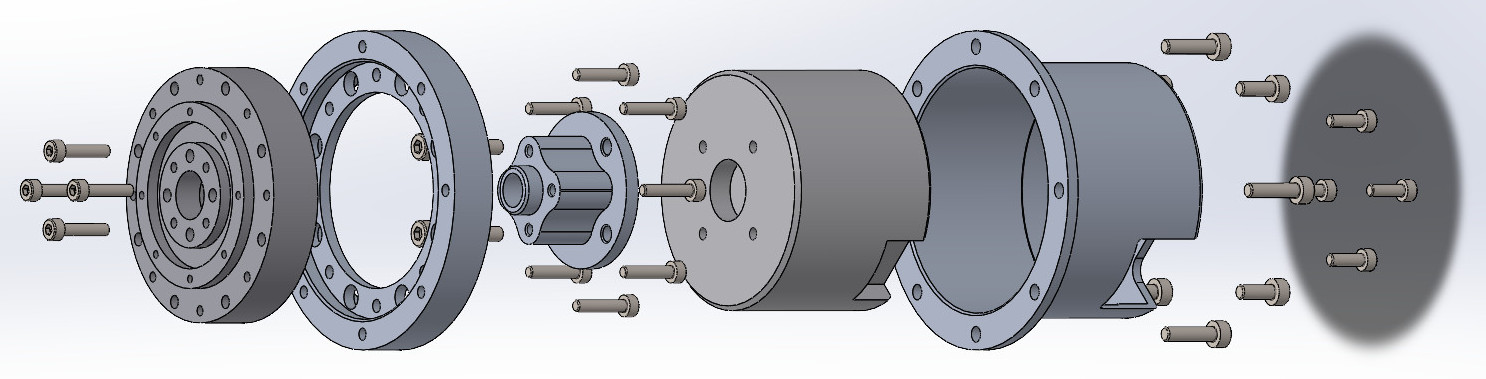

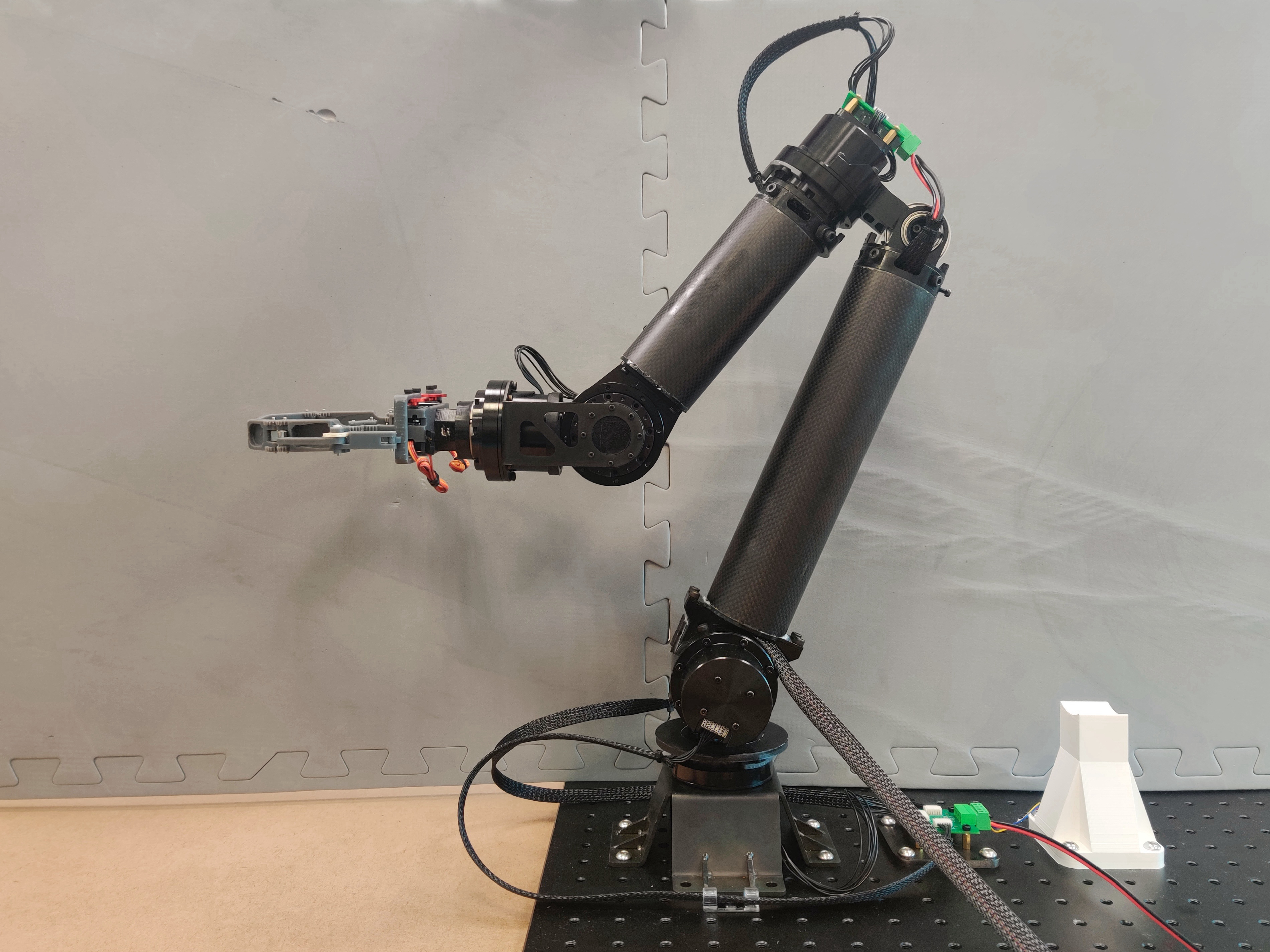

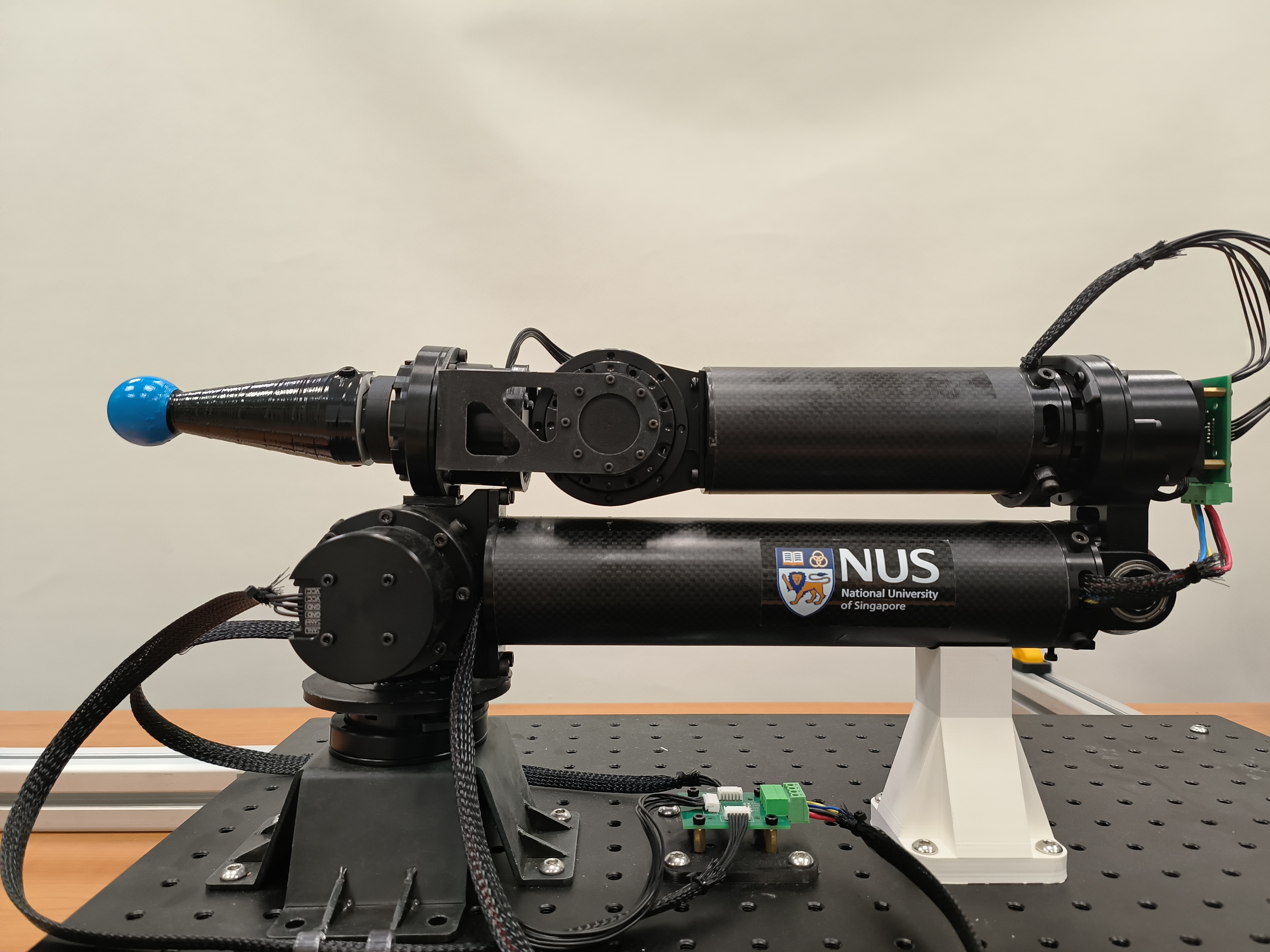

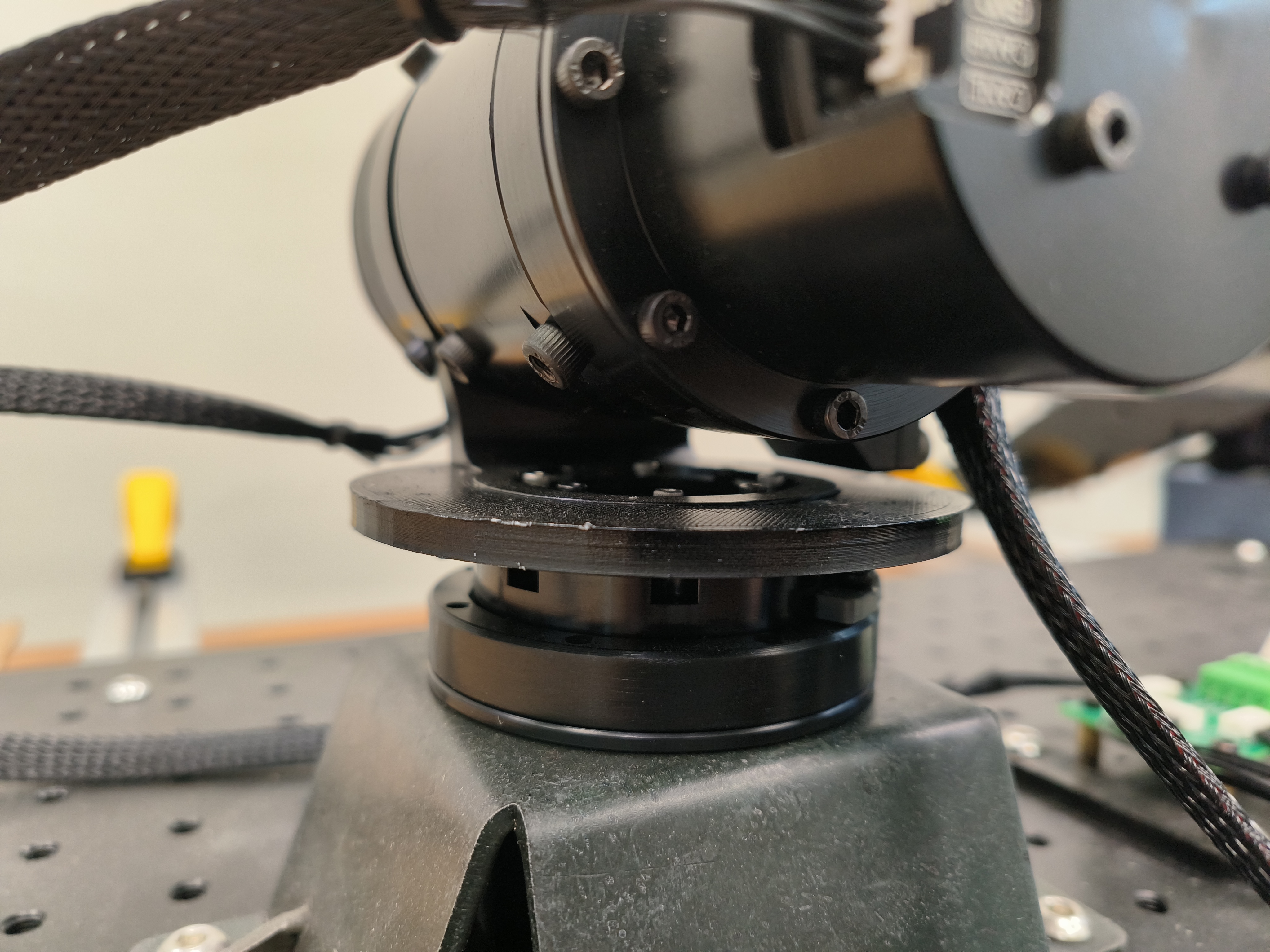

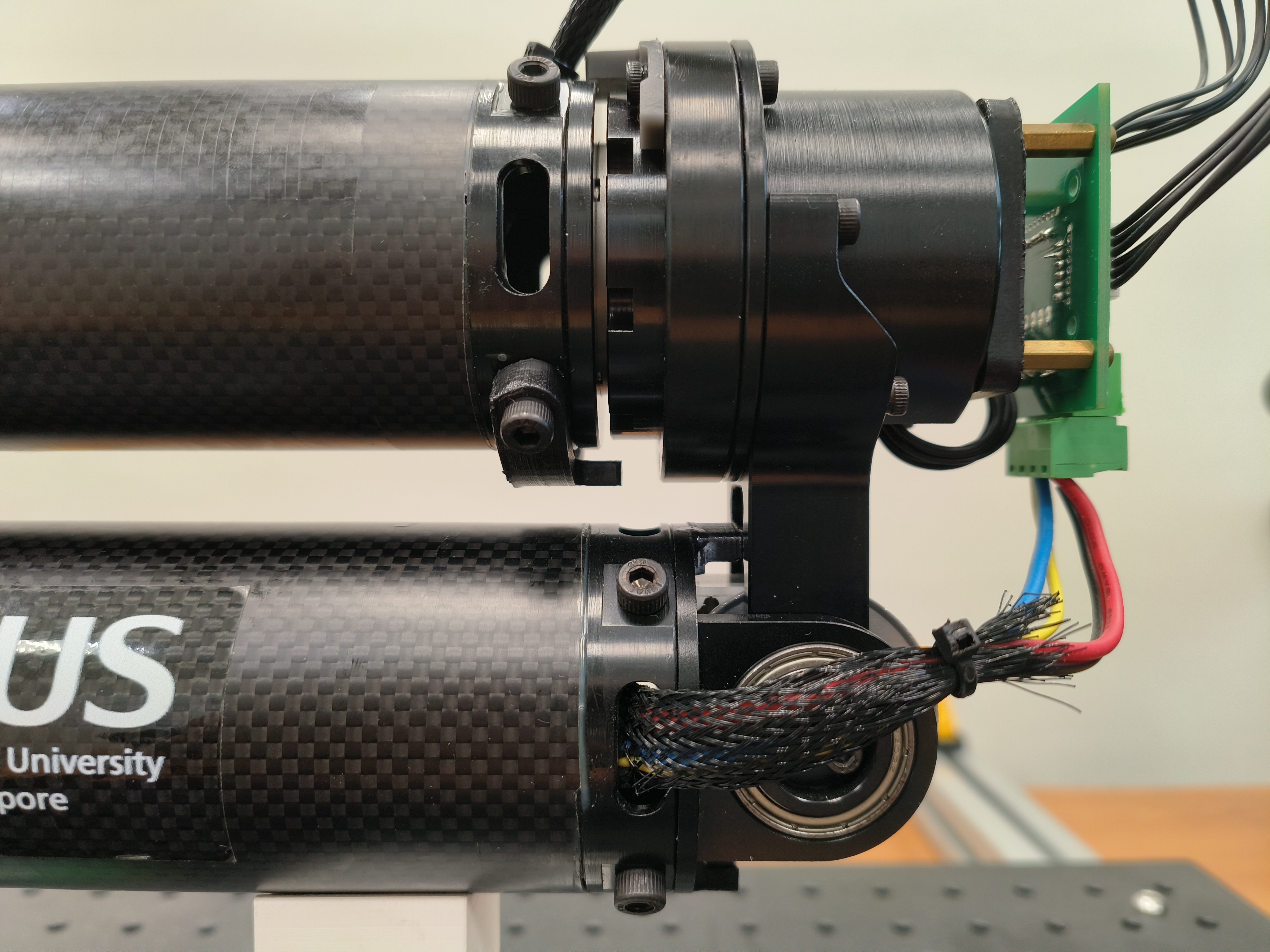

The actuator, as the core component of the robot, is a (brushless DC electric) BLDC motor (GYEMS L5010 or L5015) in series with a 50:1 harmonic reducer. The other mechanical components are customized, made of aluminum alloy, carbon fiber, or 3D-printing material.

The robot assembly looks so exquisite!

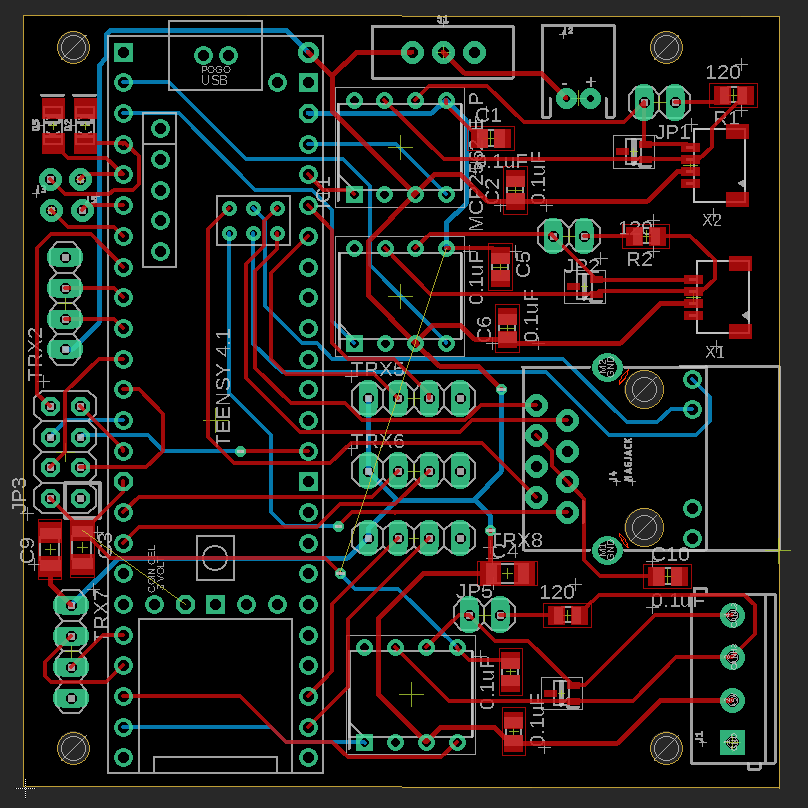

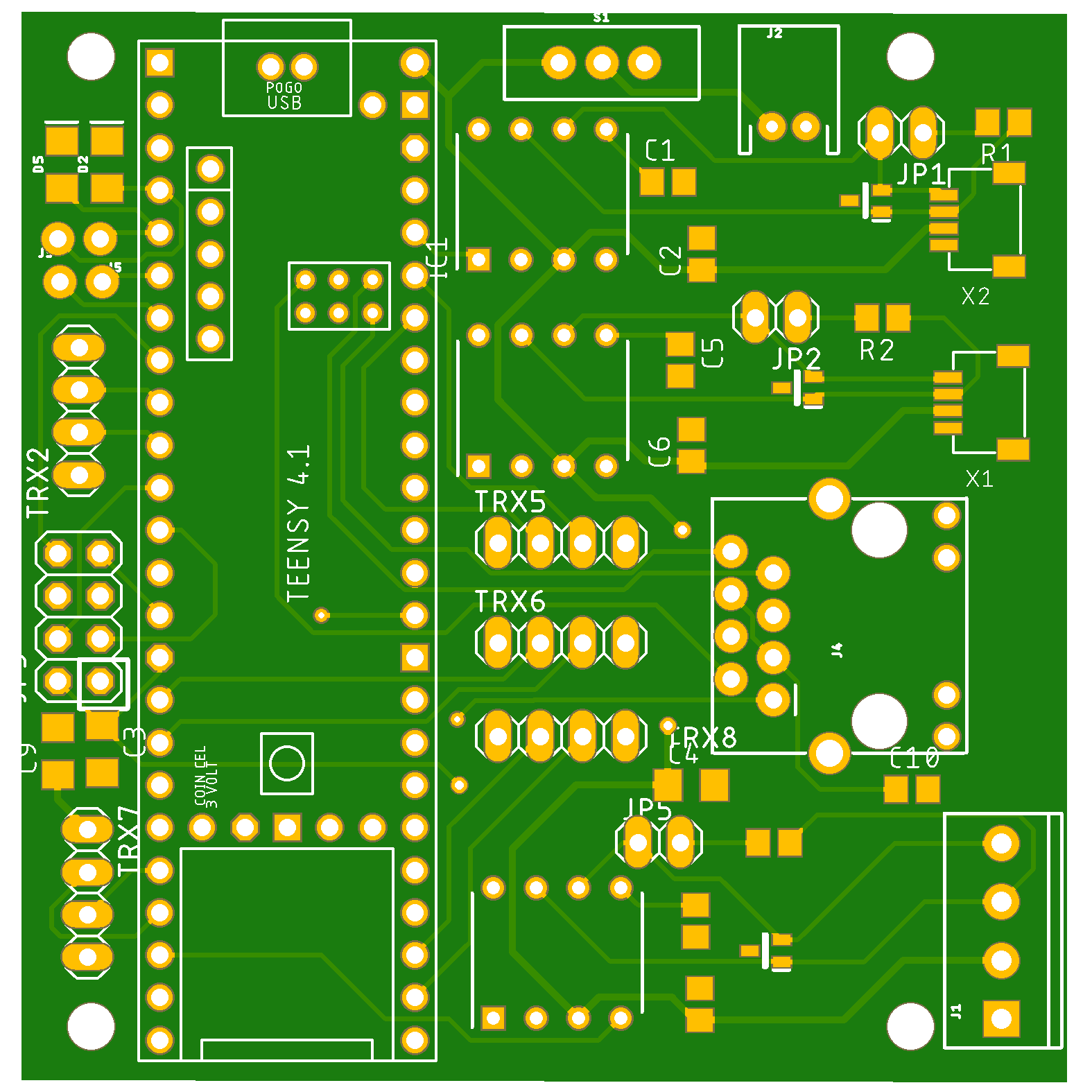

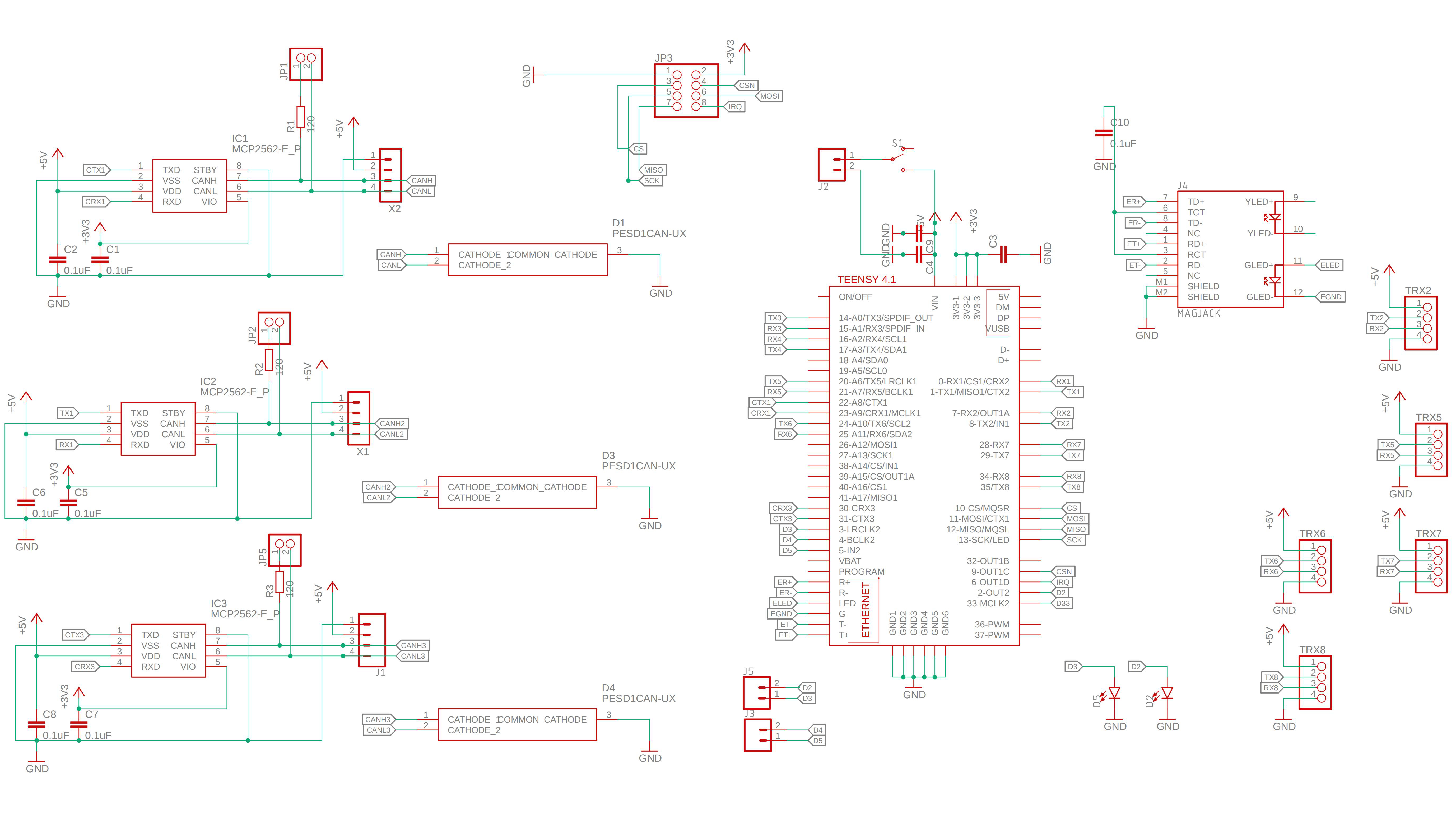

Regarding its electronics, we design a two-layer PCB board based on Tennsy 4.1 to process data from various devices.

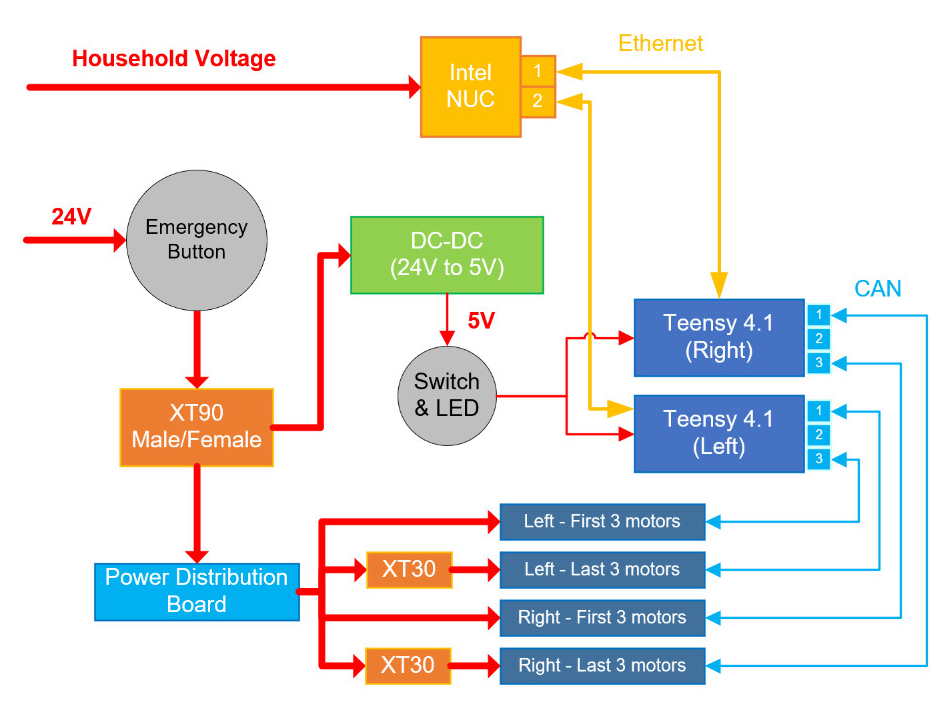

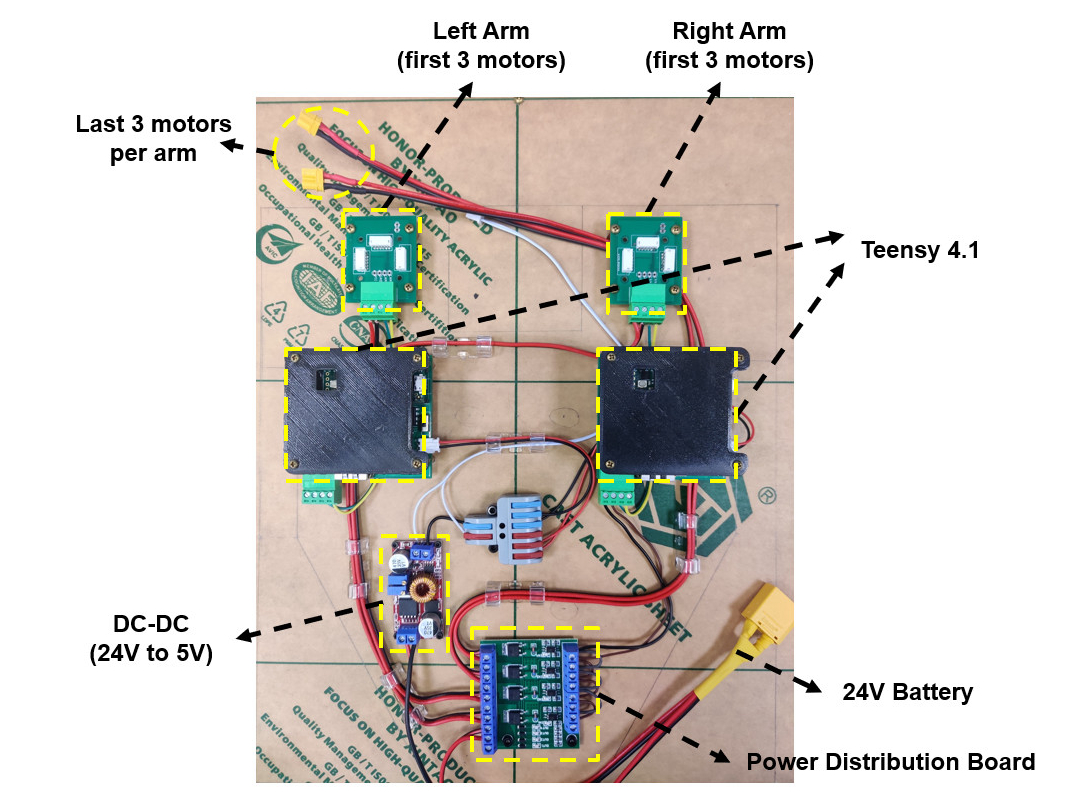

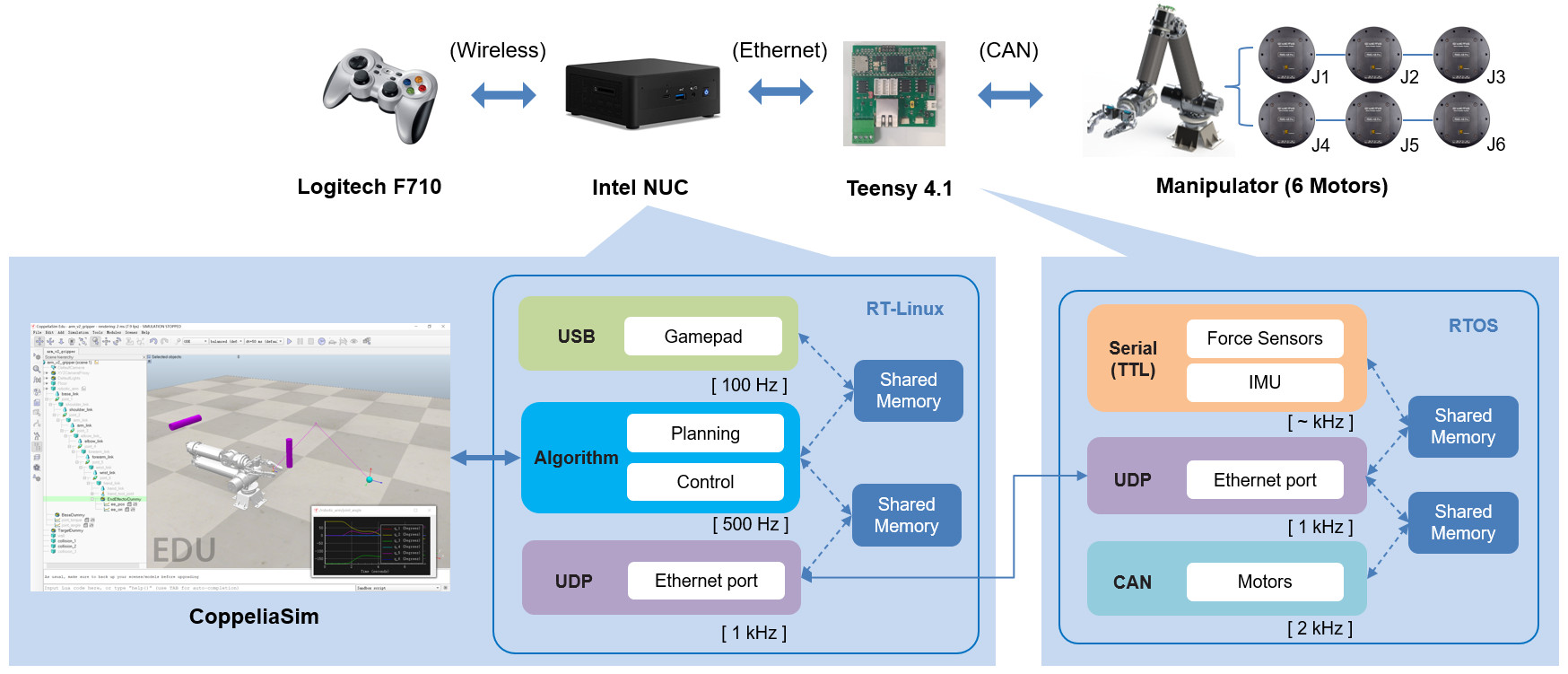

The robot shares the same electronics as our bimanual cobot: an Intel NUC computer, Tennsy 4.1 microcontrollers, etc.

In addition, we develop a real-time software architecture where the code can run in multiple threads under strict time constraints. Excitingly, the low-level code for the Tennsy 4.1 has been open-sourced. Please see the repository.

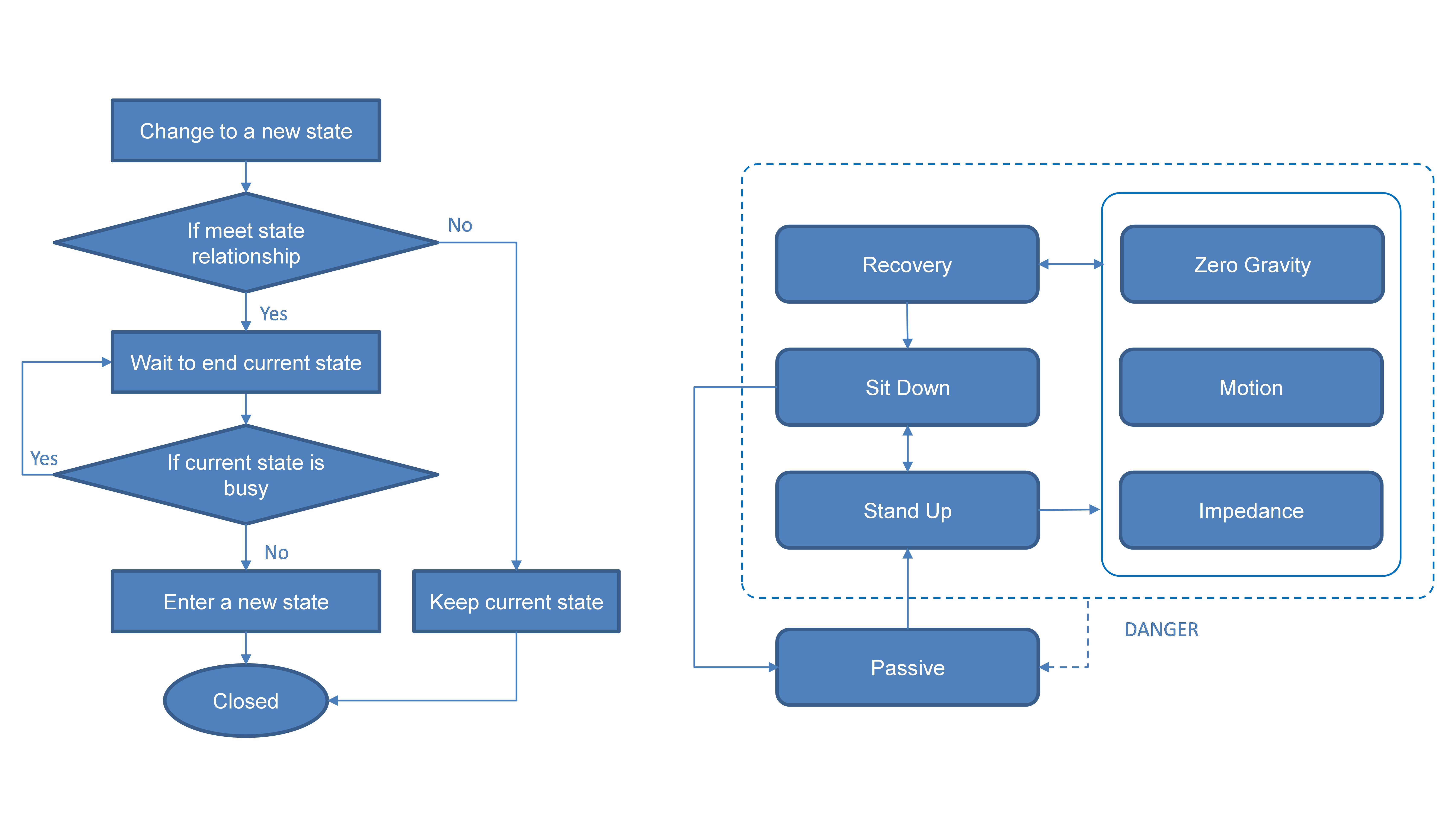

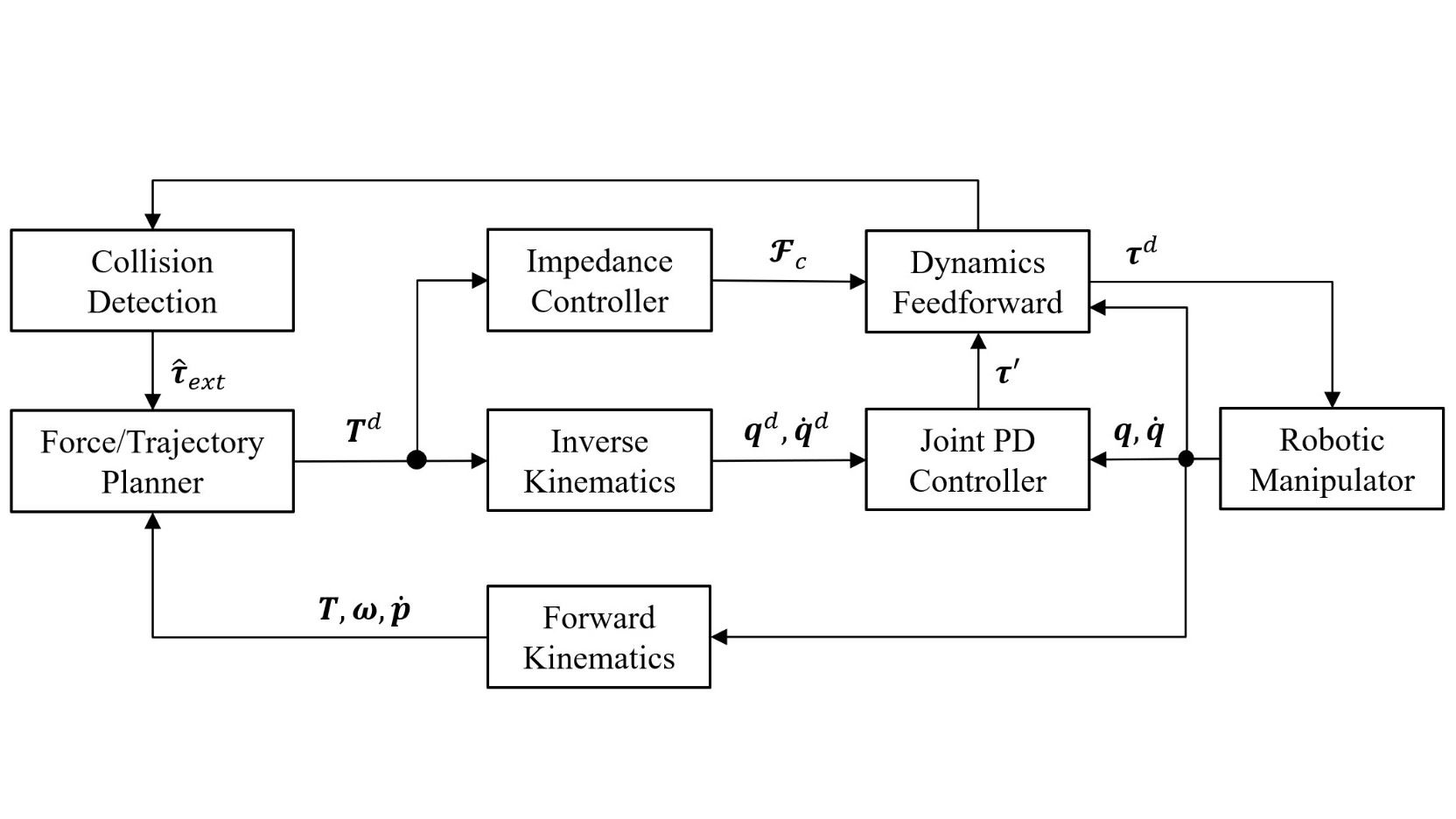

The robot has a hybrid force and motion control framework. It can follow a trajectory in joint space or Catersian space, and also support compliant physical interaction. As the dynamics is available, the robot can detect unexpected collisions using only proprioceptive data, thus ensuring the safety of humans and itself. Furthermore, we design a finite state machine (FSM) to manage different robot states.

Simulations in CoppeliaSim validate the effectiveness of the algorithm. Hardware experiments are also conducted for verification.